17 May 2024

17 May 2024If you are not familiar with the different types of machinery used in the processing industry, then the term "slitting machine" may be completely unfamiliar to you. Knowing what a slitting machine is and how it works can help you make the right purchase decision when you equip your enterprise with the right machinery. Learn all about the working principle of the slitting machine by reading the following blog!

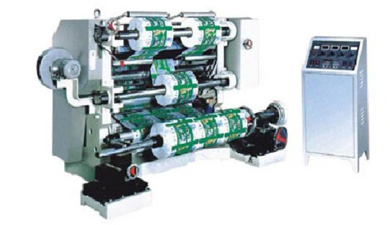

Slitting machine is a kind of equipment used to cut continuous roll materials (such as paper, plastic film, metal foil, etc.) into required width. It is mainly used in packaging, printing, manufacturing, food processing and other industries, as well as in the processing and manufacturing process of various materials.

The key parts of this device are the unwind, the rewind, and the slitter. An extensive roll of film-like material enters the unwind. Here, it's sliced into precise widths, then rewound to lesser dimensions. Commonly seen everyday examples include retail store receipts. These start life on a larger master roll, then get slit down to your received size.

The working principle of the slitting machine usually includes:

1. Feeding: A continuous roll of material is introduced into the working area of the slitter.

2. Positioning: accurately position the roll material to ensure the required width and length when cutting.

3. Cutting: The cutting part is the key of the slitting machine, including a cutter or a cutting wheel, which cuts the continuous roll of material into single or multiple pieces as required.

4. Collection or discharge: the cut strips can be collected for subsequent processing or packaging, or they can leave the slitter through the discharge system.

slitting machine usually has a high degree of automation and accurate cutting ability, which can meet the requirements of different industries for material processing accuracy and production efficiency. At the same time, some slitting machines are equipped with automatic adjustment, detection and debugging functions, which improve the stability and reliability of the equipment and reduce the working intensity of operators and the possibility of misoperation.

GET A QUOTE