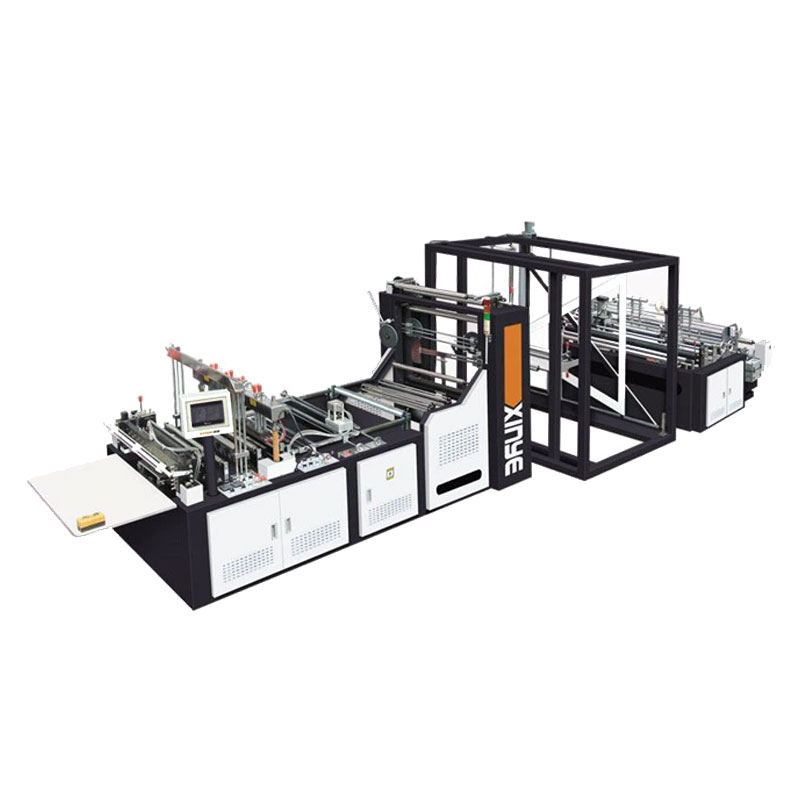

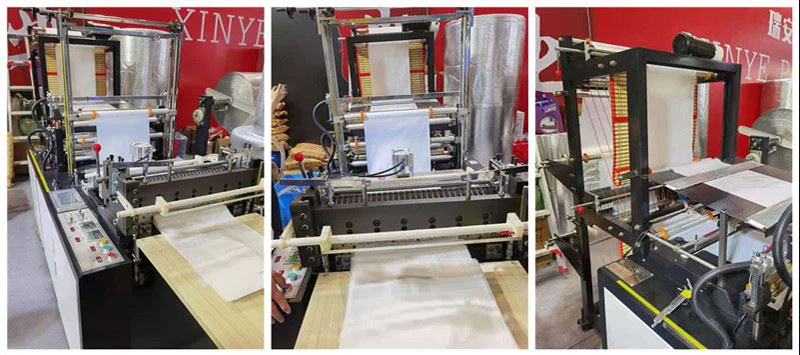

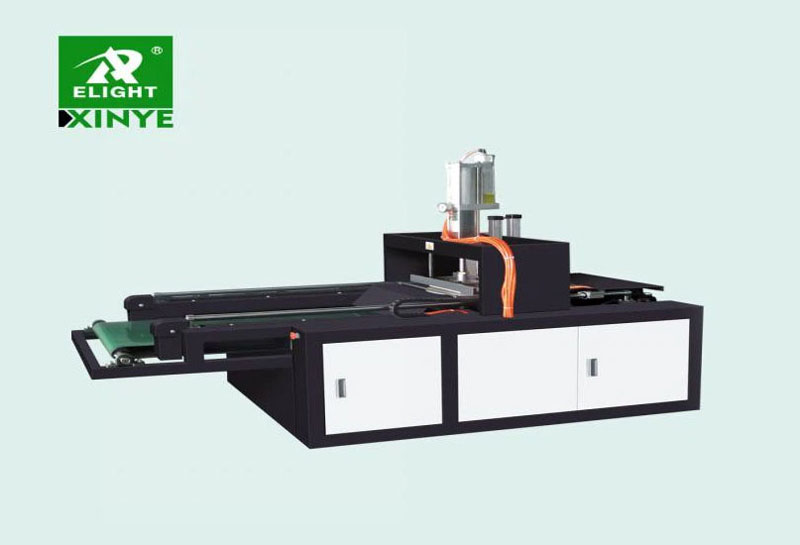

Biodegradable Bag Making Machine

This Biodegradable Plastic Bag Making Machine is designed to make biodegradable bags. The Biodegradable Bags can be changed into water, H20 and carbon dioxide, CO2, no any plastic residuum.

This Biodegradable Plastic Bag Making Machine is designed to make biodegradable bags. The Biodegradable Bags can be changed into water, H20 and carbon dioxide, CO2, no any plastic residuum.

This Biodegradable Bag Making Machinee is designed to make biodegradable bags. The Biodegradable Bags can be changed into water, H20 and carbon dioxide, CO2, no any plastic residuum.

In fact, it is sealing and cutting machine, mainly for converting the ready biodegradable film into bags of different styles, such as flat mouth bag with bottom sealing, flat mouth with hole handle, etc.

|

Model |

GFQ-600 |

|

Max width of sealing & cutting |

550MM |

|

length of sealing and cutting |

1200MM, |

|

thickness of sealing and cutting |

0.006--.0.10MM |

|

error in length |

1MM |

|

speed |

40-120PCS/min x2 |

|

power of main machine |

1.1KW |

|

inverter of main machine (Huifeng Brand) |

1.2KW |

|

Heating Power |

2.5KW |

|

Total Power |

7kw |

|

DC motor (made in China) |

2 |

|

Step motor (made in China) |

1 |

|

DC motor of Unwinding |

2 |

|

D cut punching |

1 |

|

Unwinding photoelectric tracking |

2 |

|

Steel hot knife |

2 |

|

front knife: steel |

1 |

|

Photo-cell |

1 |

|

PLC |

1set |

|

temperature control meter |

2pc |

|

switch :schneider |

1set |

|

machine weight |

800Kg |

|

overall dimensions |

2650*1200*1550mm |

GET A QUOTE