Description:

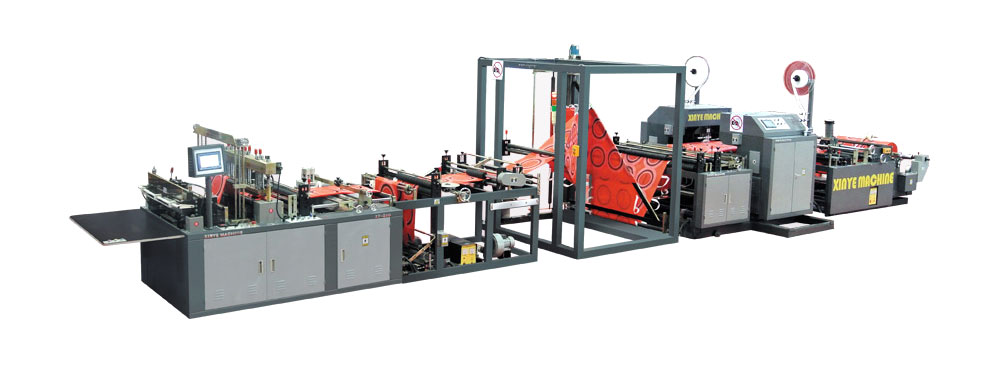

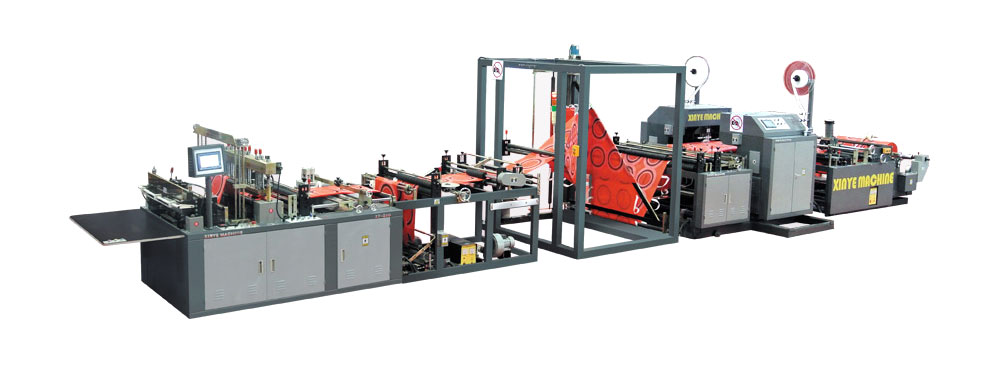

This Loop Handle Non Woven Bag Making Machine is the present domestic function is the most complete, the performance is the most stable automatic non-woven bag making machine. On the basis of the original bag making machine, add automatic bonding handle. That is real liberating manual and fully automatic production of non-woven bag. It compared with the similar machine, higher precision, less waste, faster and achieved maximum benefit for you

A loop handle nonwoven bag making machine is a specialized piece of equipment designed to manufacture nonwoven bags with loop handles. These loop handle bags are commonly used for shopping, carrying items, and promotional purposes. The machine is designed to automate the process of producing these loop handle nonwoven bags efficiently and accurately.

Process flow:

This Loop Handle Non Woven Bag Making Machine widely used in producing non-woven handle bag, flat bag,The produce different bags as long as change the way of material. It is simple operation, high efficiency and good stability. The whole machine adopts microcomputer control and material pulling by stepping motor. Automatic positioning and bonding handle. It arbitrary fixed length, accurate and stable step photoelectric tracking, automatic punching, counting, alarming and stopping when the label is lost.

Raw material→bag mouth folding→thermal bonding→folding up→loop handle fix→positioning→thermal bonding→bag cutting→collecting

Features:

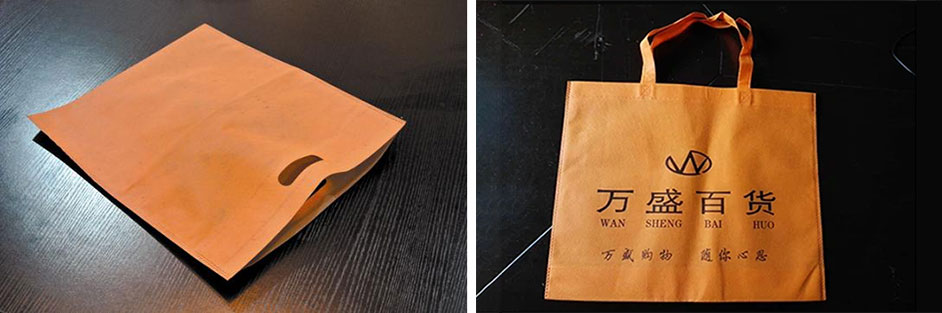

1.Loop Handle Design: The machine is designed to create nonwoven bags with loop handles attached, providing a convenient and comfortable way to carry the bag.

2.Automated Processes: The machinery includes automated processes for material feeding, cutting, folding, handle attachment, sealing, and bag formation, ensuring consistent and high-quality production.

3.Material Compatibility: It works with nonwoven fabric, a durable and eco-friendly material commonly used for reusable bags.

4.Handle Types: The machine can produce loop handle bags with different handle styles, such as die-cut handles or stitched handles.

5.Customization (Optional): Some machines may come equipped with printing units for adding logos, branding, or designs onto the nonwoven bags.

Technical Parameters:

|

Model

|

XY-700

|

|

Bag width

|

100-800mm

|

|

Bag height

|

220-650mm

|

|

Loop handle length

|

370-560mm

|

|

Bag making speed

|

40-120pcs/min

|

|

Total power

|

15kw

|

|

Air source

|

1.0m³/min, 0.8 Mpa

|

|

Voltage

|

380V,50hz,3-phase 4-line

Single phase 220v

|

|

Overall dimension(L*W*H)

|

12×3.5×2.1m

|

|

Machine weight

|

4000kg

|