Description:

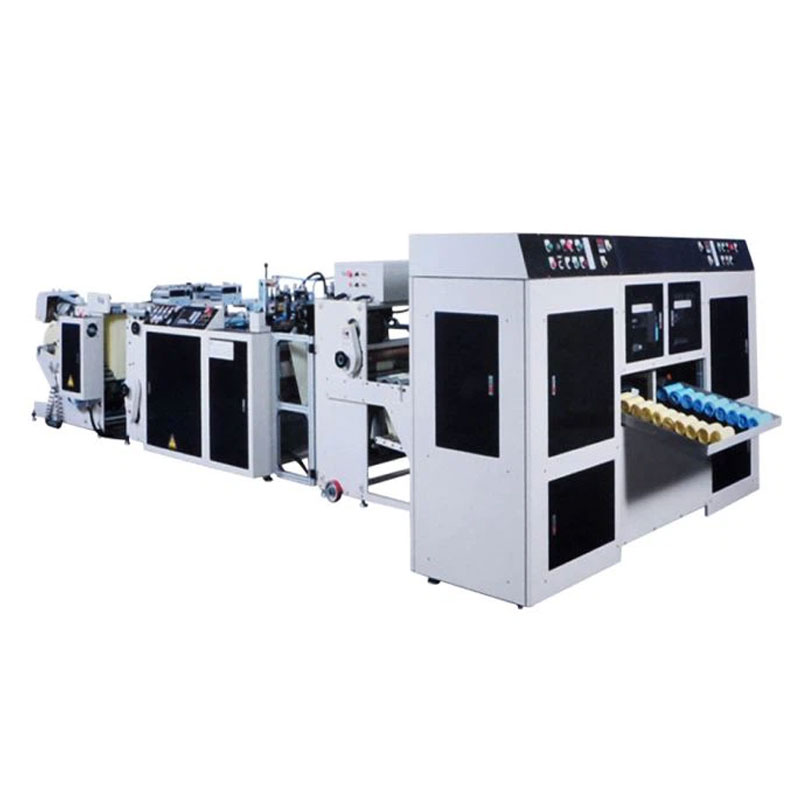

A hot cutting rolling bag making machine is a specialized piece of equipment used to automate the process of manufacturing plastic bags with hot cutting and rolling features. These machines are commonly used to produce various types of plastic bags, such as T-shirt bags, flat bags, and other roll-type bags, with a neat and sealed cut edge. The hot cutting and rolling process ensures that the bags are efficiently cut, sealed, and rolled for easy dispensing.

1.This hot cutting rolling bag making machine has been improved designed and manufactured by our company's professional workers and experienced designers.

2.Computer control and material-pull motor composition model are used.

3Multiple functions. Photoelectric tracking, bags color bags change function, microcomputer length setting, automatic counting, and automatic alarm on reaching the set value.

5.This machine adopts no tension techonology to seal an organization, seal and cutting-off synchronously, bottom film beautiful.

6.This product adopts process continuous-rolled ribbon-though type garbage, continuous-rolled flat bags and flat bags function.

Features:

1.The machine is equipped with a heated cutting mechanism that cuts the plastic film while simultaneously sealing the edges to prevent fraying.

2.After cutting, the machine can roll the bags into a compact roll, making it easy to dispense and store the bags.

3.The machine's automated processes include material feeding, cutting, sealing, rolling, and bag formation, ensuring consistent and high-quality production.

4.It works with various types of plastic materials suitable for bag production, such as polyethylene (PE) or polypropylene (PP) films.

5.Some machines may offer customization options, such as printing or labeling, for branding or additional information on the bags.

Technical Parameters:

|

Model

|

XYWX-450*2

|

|

Bag width

|

100-250mm

|

|

Bag length

|

200-1500mm

|

|

Bag thickness

|

0.008-0.035mm

|

|

SpeeF

|

100m/min

|

|

Unwinding material diameter

|

Φ900mm

|

|

End product diameter

|

Φ150mm

|

|

Air compressor

|

6hp

|

|

Total power

|

12.5kw

|

|

Machine weight

|

3350kg

|

|

Overall dimension

|

7500*1750*1700mm

|