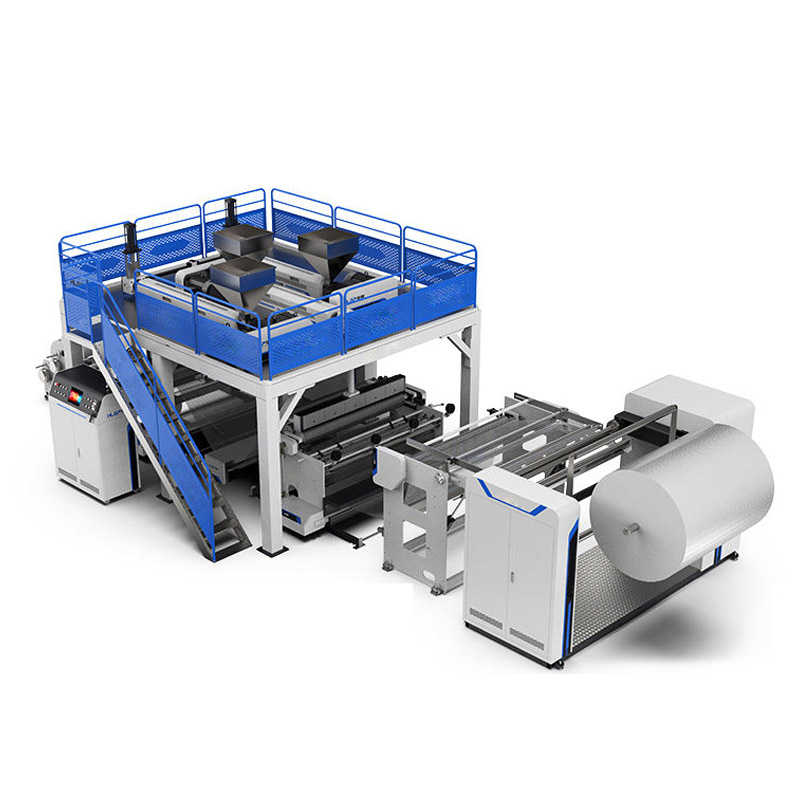

Two-Layers Co-Extrusion Stretch Film Making Machine

The double-layer co-extrusion stretch film making machine is specially designed for the production of stretch films with double structures. Its excellence lies in that it can effectively prevent the risk factors such as moisture, dust, pollution and mildew faced by goods during long-distance transportation, and it also has the functional advantage of stabilizing the shape of goods.