The film blowing machine is one of the indispensable and important equipment in the plastic processing industry. Its core function is to process plastic particles into films by extrusion, heating and inflation. Films are widely used in packaging, agriculture, construction, industry and daily life, and are one of the most common forms of modern plastic products. So, what is the use of film blowing machines? This article will deeply analyze the main uses of film blowing machines and their important value in practical applications from multiple angles.

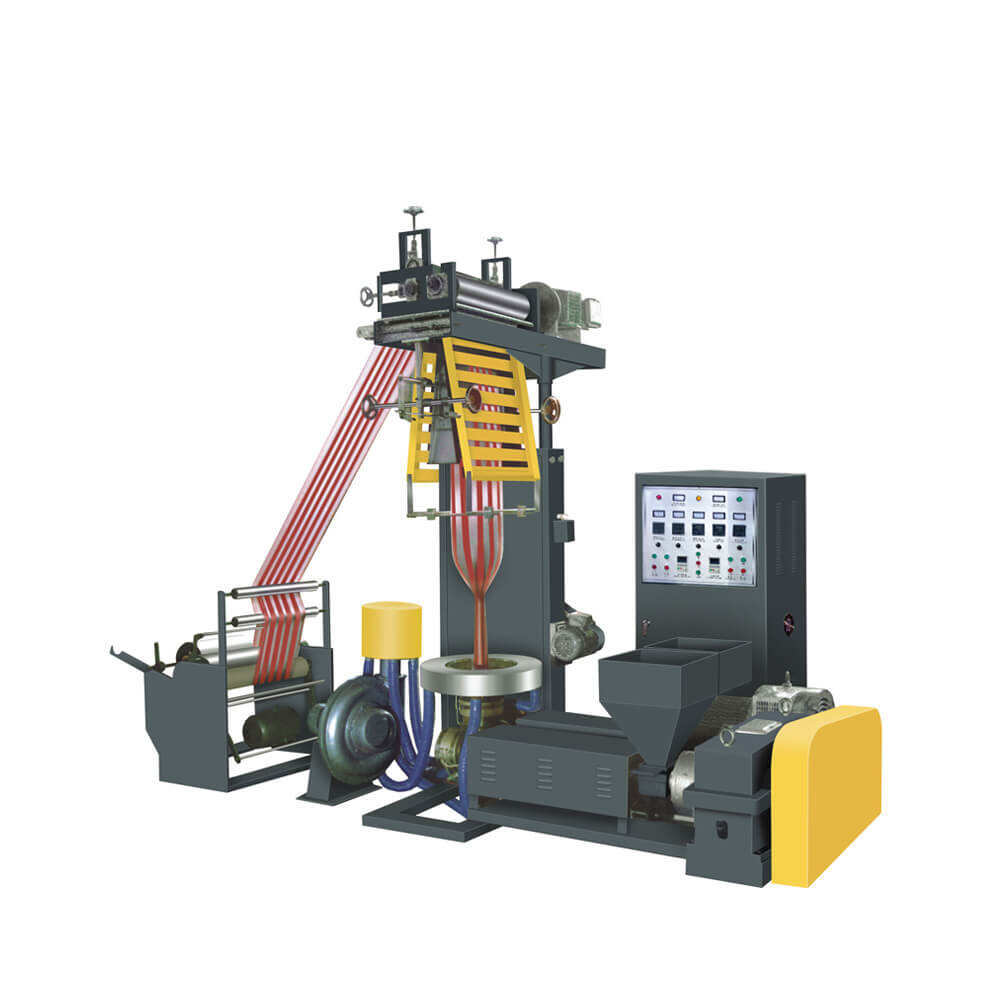

1. Working Principle

The film blowing machine heats and melts plastic raw materials (such as polyethylene PE, polypropylene PP, etc.) and extrude them, passing through the die to form a cylindrical film embryo. At the same time, compressed air is blown into the film embryo from the center of the die to expand it into the required tubular film. After that, it is cooled, pulled and rolled to make a plastic film of a certain thickness and width.

2. Main Types of Film Blowing Machines

Ordinary PE film blowing machine: used to produce films for daily packaging bags.

- Multi-layer co-extrusion film blowing machine: used for high-performance films such as food packaging and high-barrier packaging.

- PP film blowing machine: mostly used for transparent film products such as stationery covers and file bags.

- High and low pressure co-extrusion film blowing machine: Combining the performance of high pressure (LDPE) and low pressure (HDPE) materials, it is more widely used.

- Agricultural film blowing machine: specially designed for the production of agricultural covering film and greenhouse film.

3. The Applications of Film Blowing Machine

3.1 Production of Plastic Packaging Bags

This is the most common use of film blowing machine. Plastic packaging products such as shopping bags, garbage bags, vest bags, roll bags, etc. on the market are almost all produced by film blowing process. According to different needs, film blowing machine can adjust thickness, width, strength and color to adapt to various commercial and life applications.

3.2 Food Packaging Film

Multi-layer co-extrusion film blowing machine is widely used in the production of food packaging film, such as vacuum packaging film, frozen food packaging, cooked food packaging, etc. These films not only require high transparency, but also have good heat sealing, oxygen barrier, moisture resistance and ductility. Using the film blowing process, the combination of multifunctional film layers can be achieved in a single molding process.

3.3 Agricultural Film

Agricultural greenhouse film, ground film, cling film, etc. are also important application areas of film blowing machine. This type of film needs to have strong UV resistance, aging resistance and tensile strength, and is usually produced by a large-caliber agricultural film blowing machine. For example, in greenhouse cultivation, greenhouse film can increase crop yields and extend the growth period, greatly improving the level of agricultural modernization.

3.4 Industrial Film

Industrial packaging has high requirements for film thickness, toughness, and chemical stability. Common applications include heavy-duty packaging bags, shrink films, wrapping films, anti-corrosion films, etc. High-strength film blowing equipment can meet these needs. For example, in the fields of building materials, chemicals, minerals, etc., the film produced by the film blowing machine can effectively protect the safety of goods during transportation and storage.

3.5 Daily Necessities Film

For example, tablecloths, shower curtains, folder covers, etc., these soft film products used in daily life are also mostly made by film blowing machines. By controlling the formula and film blowing process, soft, transparent, and decorative film materials can be obtained.

3.6 Medical Packaging Film

Medical devices, drugs, etc. have extremely high requirements for the safety and sealing of packaging films. Multi-layer co-extrusion blown film technology can achieve functions such as sterility, impermeability, gas barrier, and stretch resistance. It is often used in the manufacture of drug packaging bags, disposable infusion bags, etc.

Summary

As the core equipment for plastic film manufacturing, film blowing machines are widely used in many fields such as packaging, agriculture, industry, medical care, and home furnishing. Whether it is daily shopping bags or high-end food and drug packaging, they are inseparable from the support of film blowing technology.

FAQ

1. What are the primary uses of film blowing machines?

Film blowing machines are primarily used to produce polymer films for applications including food and industrial packaging, greenhouse films, medical-grade sterilization films, and construction moisture-control layers.

2. What kind of materials are processed in film blowing machines?

Film blowing machines can process a wide range of materials, including high-density polyethylene (HDPE) and biodegradable polylactic acid (PLA), among others, to create films that meet various industry specifications.

3. How does temperature affect the film blowing process?

Temperature settings are critical, as incorrect temperatures can affect the bubble stability and tensile strength of the film. Proper thermal regulation ensures uniform material flow and prevents defects during the process.