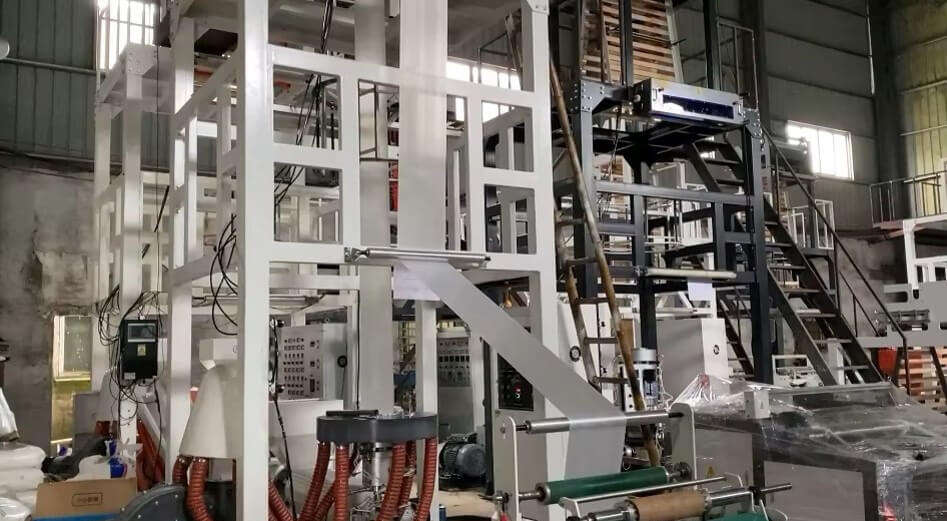

To increase your production efficiency, choose our high speed film blowing machine unit (Model B). This equipment uses advanced technology to quickly and stably produce a variety of plastic films for packaging, agricultural and industrial applications.

The cylinder and the screw stems of blown film extrusion are made of high-quality alloy steel with optimum hardness and strong corrosion resistance after precision finishing and nitrogen treatment.

The pe film extruder can be lift up to 3meters according to the technological requirements. Mode of film blowing:bottm blowing. The coiling unit adopts torque motor to keep proper tension and make rolling even and roll-changing easy.

| Model | SJ-50/FM600 | SJ-55/FM800 | SJ-60/FM1000 | SJ-65/FM1200 |

| Screw Diameter | 50mm | 55mm | 60mm | 65mm |

| Screw Ratio | L/D32:1 | L/D32:1 | L/D32:1 | L/D32:1 |

| Screw Speed | 10-150r/min | 10-150r/min | 10-150r/min | 10-150r/min |

| Power o Main Motor | 22kw | 30kw | 37kw | 45kw |

| Max.Extrusion Output | 30-70kg/h | 40-100kg/h | 50-120kg/h | 50-140kg/h |

| Max.Folding Width of Film | 600mm | 800mm | 1000mm | 1200mm |

| Thickness of Film | 0.008-0.10mm | 0.008-0.10mm | 0.008-0.10mm | 0.008-0.10mm |

| Lift Range of Auxiliary Machine | 800mm | 800mm | 800mm | 800mm |

| Total Power | 45kw | 55kw | 66kw | 78kw |

| Weight of Machine | 3000kg | 3500kg | 4000kg | 480Okg |

| Overall Dimension(LxWxH) | 4.6x2.6x6.3m | 4.8x2.8x6.5m | 5.0x3.0x7.0m | 5.5x3.5x7.5m |

1. Automatic feeder

2. Corona treatment machine

3. Mold rotation device

4. Air compressor

5. High-speed screen changer

Its extruder, cylinder, and screw are made of high-quality alloy steel with optimum hardness and strong corrosion resistance after nitrogen treatment and precision processing. The specially designed screw enhances plasticizing of film, which helps increase the production capacity.

The high speed film blowing machine is applied to blowing plastic films like low-density polyethylene (LDPE), high-density polyethylene (HDPE), and linear low-density polyethylene (LLDPE). It is widely applied to producing packaging bags for foodstuffs, clothing, rubbish, and so on.

1.Are you a factory or trading company?

We are established in 1995, an actual factory and manufacturer in the line of printing and packing machine for 20 years.

2.Where is your factory loaded? How can I visit there?

Our factory located in Rui'an city, Zhejiang Province, China, about one hour by air from Shanghai. All our clients, from home or abroad, are warmly welcome to visit us.

3.Which industries are widely used in of your machine?

Bag making machine, film blowing machine, printing machine.

4.How about the payment term?

For new customer, our payment term is 30% T/T in advance before production, the balance 70% should be paid before delivery.

5.What about your main market?

Our products be sold well in 30 provinces in China and have good reputation in China, also we pay attention to developing the oversea market, such as Europe, Russia, Southeast Asia, Middle and South America, Africa, and other countries.

6.How does your factory do regarding quality control?

Quality is the most important principle. GREAT WALL always attach great impartance to quality controlling from the every beginning to the every end. Our factory has passed SGS and CE certifications.

Copyright © 2025 Ruian Xinye Packaging Machine Co.,Ltd | Privacy policy