Blown film machines: the universal solution for every industry

When it comes to plastic film production, the right blown film machine makes all the difference. From small factory to large factory, we have machines to utilize every requirement from primitive packaging function to high performance in industrial use.

Who can utilize the blown film machines?

Our blown film machines support numerous industries, that all require consistent, high-quality plastic film:

Food and Beverage Packaging: A fully transparent, moisture-proof film for snacks, frozen foods, and beverage packaging.

Agriculture: Capable of producing ground film, greenhouse film and silage film that can adapt to outdoor environments.

Daily Chemical Packaging: Can produce durable films for detergent bottles, cosmetic packaging and personal care product packaging.

Industrial Packaging: Can produce durable film for detergent bottles, cosmetic packaging, and personal care product packaging.

Small business: Compact models for local producers who need customized or small-volume films.

Our Key Models & What Makes Them Stand Out

1. One Layer Two Head Twin Head Film Blowing Machine

|

With its uncomplicated structure and improved productivity, actual customers of small and medium-sized producers value the high efficiency of this model. It transports PE material easily and produces single layer films between 0.008 and 0.1 mm thickness. The twin head model produces two rolls of film at once giving higher output with no additional complication to operations. |

2. Three to Seven Layers Co-extruding Traction Rotating Film Blowing Machine Set

|

It suits the sectors producing high barrier, flexible films that are particularly versatile (particularly food packaging that requires a block to oxygen or moisture). As it is possible to layer a number of different resins together, it can produce films with better strength, flexibility or better heat stability. The control system is accurate in distributing the requested layers for stable performance when mass producing. |

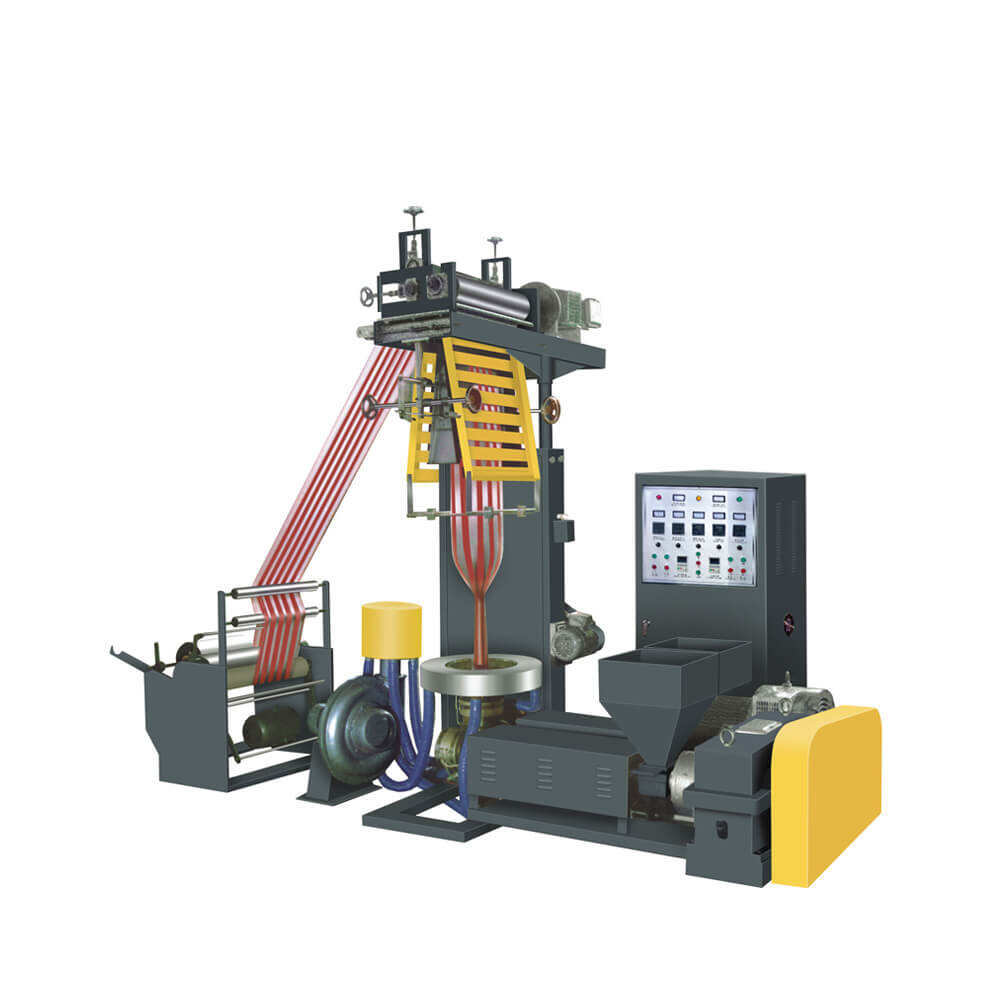

3. Double Color Film Blowing Machine

|

If your film is planned to be printed with a visible brand logo, warning message, or just to have color differentiation (Fertilizer bags, industrial and bulk production packages, etc, etc.), then using this model with the 2 color extruders allows the equal addition of both clear and even stripes added to the original base film. Using the machine would allow you to choose both the size and position of the stripes, so there is no need to stop continuing production delays from meeting specific design requirements. |

4. ABA Mini Film Blown Machine

|

It is small in stature but not in strength, and definitely appeals to small retail stores or factories that are just starting to process bags. This model's ABA configuration (A = recycled material; B = new material) mitigates cost to product without compromising on quality; making it particularly well suited for low-cost nd durable garbage bags, shopping bags, or light weight packaging film. The little machine ocupies very little ground space, which is an advantage when renting manufacturing/processing space that also includes still wanting to obtain a higher production rate without the investment of larger processing gear. |

5. Rotary Head Polypropylene Film Blowing Machine Set

|

This machine is specially designed for PP (polypropylene) film, with a rotary head design for stable extrusion and uniform film thickness. the PP film itself is strong and bright, which is suitable for gift wrapping, stationery wrapping or laminating. |

......

Copyright © 2025 Ruian Xinye Packaging Machine Co.,Ltd | Privacy policy