Among modern plastic products, plastic films are widely used in food packaging, industrial packaging, agricultural covering films, medical supplies and other fields. There are many ways to manufacture plastic films, among which blow molding is an important and widely used process, which is widely used to produce thermoplastic film products such as polyethylene (PE) and polypropylene (PP). So, how does blown film work? What are the characteristics of its process flow, equipment structure and control parameters? This article will systematically analyze the working principle and technical process of blown film for you.

1. What is Blown Extrusion Film?

Blown film is a plastic film that is extended and shaped in both the longitudinal and transverse directions by heating and molten thermoplastic plastics, extruding it into a tubular film, and then cooling and stretching it while inflating the center. Blown film usually has good mechanical properties, heat sealing and durability, and is one of the most common film production methods.

2. Working Principle

The core of blown film is the continuous process of extrusion-blowing-cooling-traction-winding, which depends on the precise control of the equipment and the thermoplastic behavior of the raw materials.

In short, its basic working principle is as follows:

- Plastic raw materials (such as PE particles) are heated and melted through an extruder;

- The molten plastic is extruded through the die head to form a tubular melt embryo;

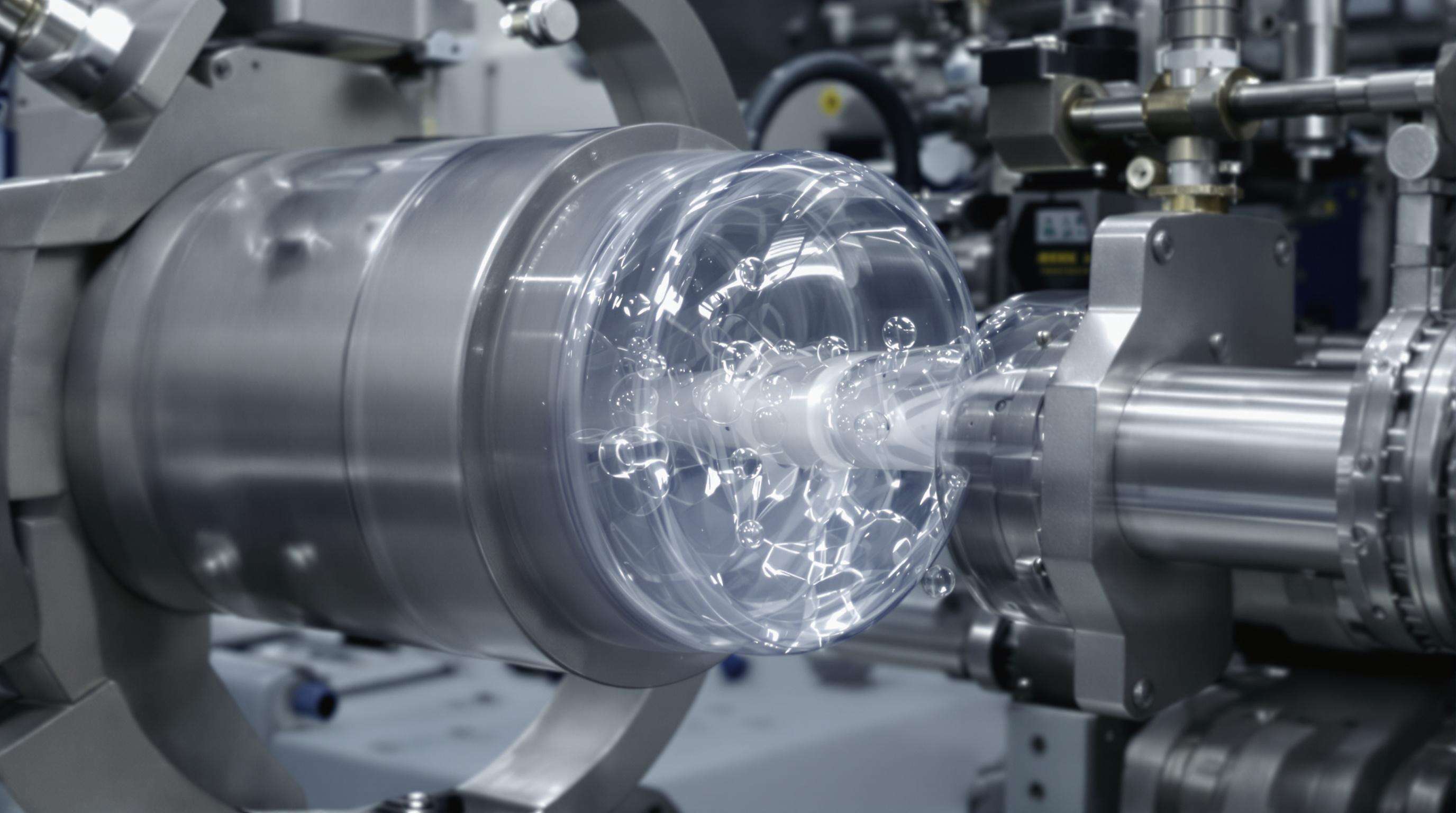

- Compressed air is filled into the middle of the tube embryo to blow it into a bubble film;

- At the same time, an air ring is used to cool from the outside to solidify the film bubble;

- The film bubble is stretched, flattened, and rolled up through the traction roller.

- This process not only achieves molding, but also controls the thickness, width, transparency and mechanical properties of the film at the same time.

3. Blown Film Extrusion Process Mechanics

3.1 Melting Polymers for Film Formation

Polymer pellets enter the extruder barrel where rotating screws and barrel heaters liquefy thermoplastic resins at 160-260°C. Maintaining temperature gradients within ±5°C ensures molecular integrity across materials like polyethylene, polypropylene, or nylon.

3.2 Bubble Creation Through Air Inflation

Air injection through the die's center orifice transforms the polymer tube into a controlled bubble. Strategically positioned air rings cool the structure while internal pressure adjusts bubble diameter, determining film properties in structures up to 40 layers.

3.3 Material Flow Dynamics in the Die

Spiral mandrel distributors balance polymer flow velocity around the 360° die circumference, preventing weld lines and thickness variations (±5% tolerance). Modern die geometries are optimized using computational fluid dynamics for resins like LLDPE.

3.4 Process Control Parameters

| Variable | Impact Range |

|---|---|

| Melt Temperature | 160-260°C resin-dependent |

| Extrusion Pressure | 100-350 bar |

| Blow-Up Ratio | 2:1 to 4:1 |

| Frost Line Height | 5-30x die diameter |

Automated feedback systems adjust extrusion rates within 0.2% precision to maintain bubble stability across production shifts.

4. Air Ring Systems Design Principles

Air rings provide primary external cooling through precisely angled airflow. Modern systems incorporate multiple chambers that manage temperature stratification, maintaining consistent surface cooling essential for high-speed production.

4.1 Internal Bubble Cooling Mechanisms

Internal bubble cooling (IBC) systems circulate chilled air through the bubble core, doubling heat removal efficiency. This enables extrusion speeds over 30% faster than conventional setups while reducing energy consumption.

4.2 Crystallization Control Methods

Polyethylene films require cooling rates above 40°C/min to limit crystal growth below 15µm. In co-extruded structures, differentiated cooling zones manage layer-specific crystalline development.

4.3 Achieving Uniform Thickness

Temperature deviations exceeding 5°C create gauge variation over 8%. Real-time infrared monitoring paired with automated air ring actuators maintains thickness tolerance within ±3% industry standards.

5. Industry Applications

5.1 Packaging Innovations

Blown extrusion films dominate flexible packaging through versatile performance. Food-grade applications leverage superior barrier properties, while medical packaging utilizes sterilizable films for IV bags and surgical instrument wraps.

5.2 Agricultural and Industrial Uses

Agriculture relies on specialized blown films like greenhouse covers and UV-stabilized mulch. Industrial applications include construction-grade vapor barriers and heavy-duty sacks for transport protection.

FAQ

1. What is blown extrusion film?

Blown film extrusion is a process that involves melting polymer resin and extruding it through a circular die to form a continuous tubular film which is then inflated into a bubble with air.

2. What materials are commonly used in blown extrusion film?

Common materials include Polyethylene (PE), Polypropylene (PP), and PVC, each offering different properties suitable for various applications.

3. What are some applications of blown film?

Applications span from flexible packaging, agricultural films, to industrial wraps and medical packaging.

4. What are the advantages of using blown film over cast film extrusion?

Blown films generally offer superior tensile strength and puncture resistance, while cast films are noted for higher clarity and production efficiency.