Facing inefficiencies in outsourced bag production, Mozambican manufacturer Interweb integrated Xinye's turnkey packaging line, achieving 200% higher efficiency, 35% gross margins, and SGS-certified quality for EU market expansion.

View More

Interweb, a leading Mozambican plastic manufacturer with 10+ years in recycled pellets, sought to produce end-use plastic bags in-house. To expand their business and add value, they sought to produce high-quality plastic bags (such as shopping bags and packaging films) in-house. However, they faced several challenges:

Limited Production Capability: Their existing equipment could only produce recycled pellets, not finished plastic bags.

Low Efficiency: Outsourcing film blowing and bag-making processes led to long lead times and high costs.

Quality Concerns: The lack of integrated production made it difficult to ensure consistent bag strength and printability.

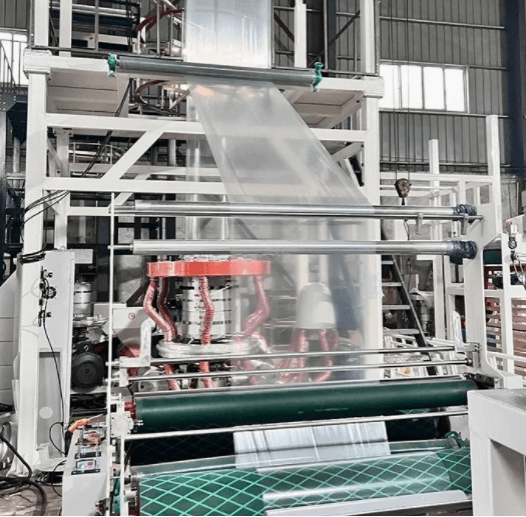

After evaluating Interweb’s needs, Xinye Packaging Machinery provided a complete production line, including:

Intelligent Recycling System: Reuses scrap material with 95% efficiency, reducing waste.

Increased Profitability: In-house production cut outsourcing costs, boosting gross margin from 15% to 35%.

Higher Output: Film production speed reached 350 kg/h, and bag-making efficiency improved by 200%.

Market Expansion: Bags met SGS standards, helping Interweb secure contracts with European retailers.

“Xinye’s machinery transformed our business—from recycling to high-value bag production. The ROI was achieved in just 6 months!”

— Interweb Production Manager

Later, Interweb reported gear wear (a consumable part) in the blown film machine. Xinye’s team promptly provided replacement parts and technical guidance, minimizing downtime.

Turnkey Solution: From pellets to finished bags, all in one line.

Data-Driven Results: Clear metrics (speed, ROI, waste reduction).

Service Commitment: Highlighting after-sales responsiveness builds trust.

Need a similar solution? Contact Xinye Packaging Machinery today!

Copyright © 2025 Ruian Xinye Packaging Machine Co.,Ltd | Privacy policy