Facing production bottlenecks and inconsistent film quality, ABC Packaging upgraded to a two-layer co-extrusion rotary die system—achieving 30% more output, 15% less waste, and faster ROI. Discover how food packaging manufacturers can meet strict EU standards while cutting downtime.

View More

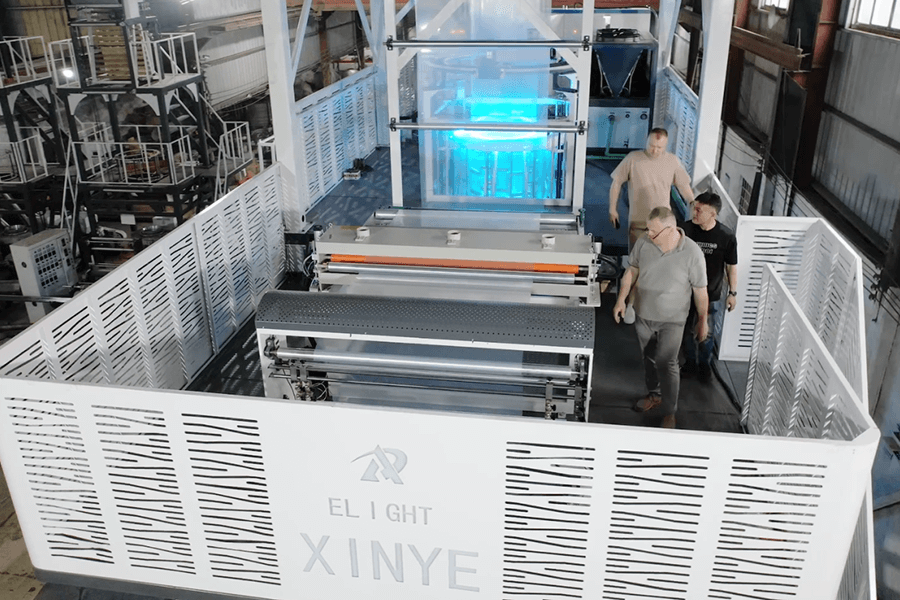

Client: ABC Packaging Co., Ltd.

Industry: Flexible Packaging Manufacturing

Location: Hanoi, Vietnam

Challenge: Needed to upgrade existing blown film line to produce high-barrier, multi-layer films for food packaging with improved output and uniformity.

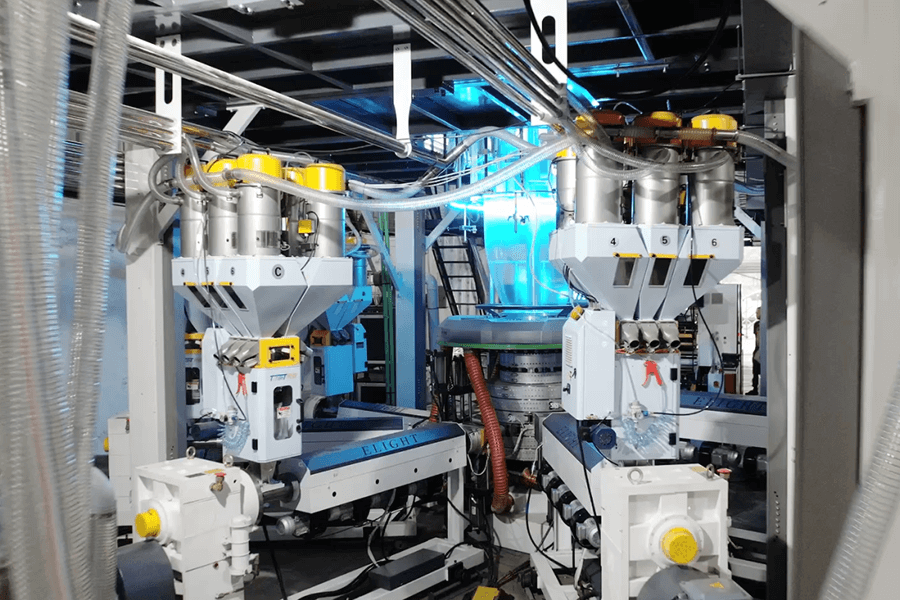

Solution: Supplied and commissioned a two-layer co-extrusion rotary die blown film composite unit with:

Output: 150 kg/h (30% increase vs. old equipment)

Layer Structure: LLDPE (80%) / EVOH (20%) for oxygen barrier

Film Width: 1200 mm ±1% thickness tolerance

From the Client’s Perspective:

"We struggled with production bottlenecks and inconsistent barrier properties in our food packaging films. The new co-extrusion system not only boosted output but also reduced material waste by 15% due to precise layer control. The rotary die design eliminated weld lines, a critical requirement for our export customers."

— Mr. Nguyen Van Tuan, Production Director, ABC Packaging Co.

Key Client Feedback:

✅ 30% higher productivity enabled faster order fulfillment.

✅ EVOH layer uniformity met EU food contact standards.

✅ Rotary die technology reduced downtime for die cleaning by 40%.

Segment: Flexible Packaging for Food & Beverage

Application: High-barrier pouches for dried foods, snacks, and coffee.

Implementation Timeline:

Week 1: Equipment delivery and installation.

Week 2: Process optimization trials (adjusted melt temps, screw speeds).

Week 3: Full production ramp-up.

Quantifiable Results:

Metric |

Before Upgrade |

After Upgrade |

Improvement |

Output (kg/h) |

100 |

150 |

+30% |

Material Waste (%) |

8% |

6.8% |

-15% |

Energy Consumption |

0.45 kWh/kg |

0.38 kWh/kg |

-16% |

Conclusion: ABC Packaging Co. achieved ROI within 14 months through higher efficiency and reduced waste, solidifying their position as a supplier for multinational food brands.

Data and testimonials sourced from ABC Packaging Co. project records (2024).

Note: Replace bolded figures (e.g., 150 kg/h) with actual data from your project. This template emphasizes measurable outcomes and client voice for credibility.

Copyright © 2025 Ruian Xinye Packaging Machine Co.,Ltd | Privacy policy