Client Background GlobalFlex Packaging is a leading manufacturer specializing in plastic vest-style shopping bags for retail chains across Southeast Asia. With increasing demand from supermarket clients, their outdated semi-automatic...

View More

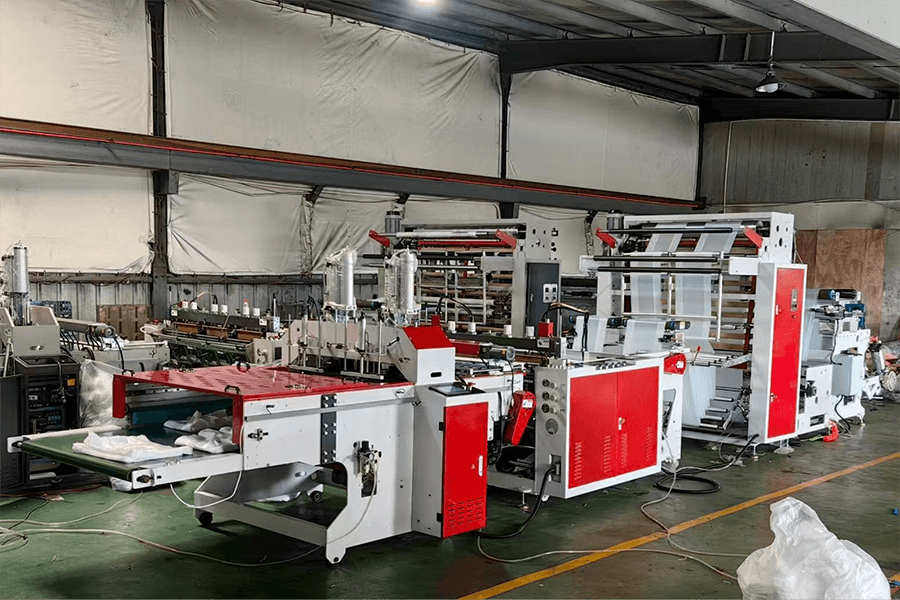

GlobalFlex Packaging is a leading manufacturer specializing in plastic vest-style shopping bags for retail chains across Southeast Asia. With increasing demand from supermarket clients, their outdated semi-automatic equipment was causing bottlenecks: slow production (max 80 bags/minute), inconsistent sealing quality, and 8-10% material waste. After evaluating multiple suppliers, they chose our fully automatic vest bag making machine to modernize their production line.

Metric |

Old Semi-Auto Machine |

Pain Points |

Production Speed (1 line) |

80-100/min |

Unable to meet peak season demand |

Defect Rate |

5-7% |

High return rate from clients |

Material Waste |

8-10% |

Eroding profit margins |

Labor Required |

3 operators per machine |

Rising labor costs |

Changeover Time |

45-60 minutes |

Frequent downtime |

- Model: XY-400*2C

- Max Speed: 380 bags*2circle/min

- Auto Features: Film feeding, handle welding, side sealing, cutting & counting

- Material Compatibility: HDPE/LDPE (30-100μm)

- Optional: CMYK printing unit

← Swipe left/right to view full table →

| Metric | Before | After Implementation | Improvement |

| Average Output (1 line) | 90/min | 380/min | 322% faster |

| Defect Rate | 6.2% | 0.9% | 85% reduction |

| Material Utilization | 91% | 98.5% | 7.5% less waste |

| Labor Efficiency | 3 labor | 1 labor | 66% labor savings |

| Energy Consumption | 11.2 kWh / 1k bags | 8.6 kWh / 1k bags | 23% more efficient |

1. Capacity Expansion

Achieved 182400bags/day (from43200 ), enabling the client to secure contracts with two major supermarket chains.

2. Quality Consistency

Implemented our patented temperature control system, reducing handle welding defects from 4.5% to 0.3%.

3. Cost Savings

- Material savings: $58,200/year (from 8% to 1.5% waste)

- Labor reduction: $21,600/year per machine

- Energy efficiency: Saves $3.8k annually

4. ROI

Full payback within 14 months through combined savings and increased orders.

"The VB-2800X transformed our business. We've not only doubled productivity but significantly improved bag strength – our clients specifically compliment the reinforced handles. The auto-counting system also reduced shipping errors by 100%. We're now negotiating for a second unit."

— Mr. Tan, Operations Director, GlobalFlex Packaging

✔ Localized Support: On-site technicians in Malaysia/Thailand

✔ Customization: Adjusted handle length for ASEAN market preferences

✔ Future-Proof: IoT-ready for production monitoring

The client plans to integrate our recycling system to reprocess trim waste into pelletized material, targeting zero-waste production by 2025.

Copyright © 2025 Ruian Xinye Packaging Machine Co.,Ltd | Privacy policy