The Evolution of Film Blowing Machines for Biodegradable Film Production

Growing Demand for Sustainable Packaging and Its Impact on Film Blowing Machine Design

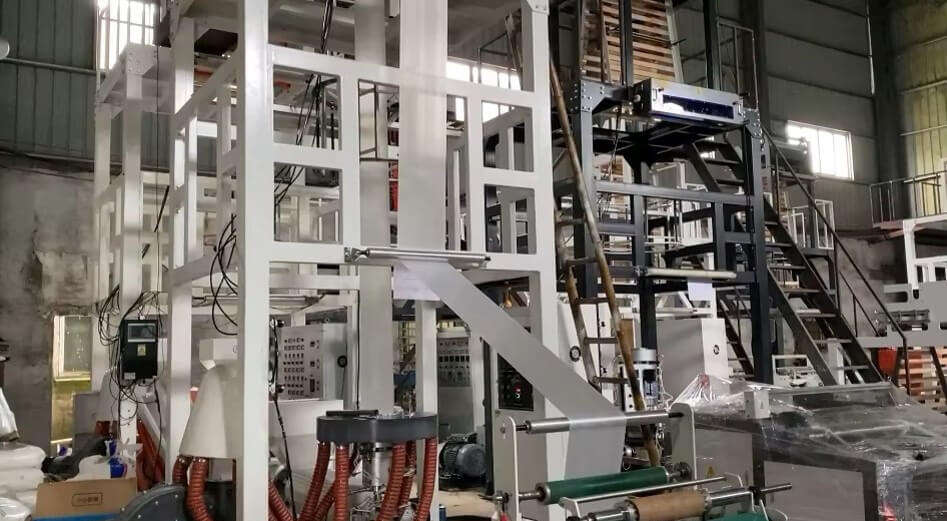

We're seeing a big change happening in the world of packaging as companies move away from plastic toward greener options. More people want their products wrapped in something that breaks down naturally, so the market for sustainable films has grown fast. This push has gotten brands thinking about what they put on store shelves. Manufacturers are tweaking their equipment to work with new materials such as PLA and PBAT instead of regular old polyethylene. These bioplastics behave differently when heated and melted compared to conventional plastics. The latest generation of film blowing machines comes equipped with better temperature management systems, redesigned screws inside the machinery, and improved cooling mechanisms. All these changes help keep production running smoothly even though working with biopolymers can be quite tricky during manufacturing processes.

How Biodegradable Materials Reshape the Blown Film Extrusion Process

Working with biodegradable materials presents some pretty specific headaches when it comes to blown film extrusion because they just don't behave like traditional plastics thermally or rheologically speaking. Take PLA for instance most processors know all too well how crucial it is to keep temperatures tightly controlled while running this stuff through the system since even slight variations can cause serious degradation issues during melting operations. These types of resins tend to crystallize differently compared to conventional polymers and generally have weaker melt strength which makes maintaining stable bubbles and proper film formation quite challenging in practice. The industry has had to get creative with equipment modifications over recent years, particularly around optimizing those critical heating zones along the barrel, redesigning air rings for better distribution, and getting much better at controlling where exactly the frost line forms on the bubble. Fine tuning everything from residence times down to cooling rates becomes absolutely necessary if manufacturers want to produce films that hold together properly while still meeting those important compostability requirements that customers now demand so strongly.

Retrofitting Traditional Film Blowing Machines for Biodegradable Resin Compatibility

A lot of companies these days prefer to upgrade their current film blowing lines instead of buying brand new machines altogether. Common improvements involve swapping out standard screws for ones that create less shear during processing, getting temperature controls down to within about plus or minus 1 degree Celsius, and adding better drying systems when working with bioplastics that get messed up by moisture. Making these changes helps achieve better consistency in the melted material, cuts down on heat damage problems, and makes it possible to produce stable batches of biodegradable films without so many issues. Retrofitting definitely saves money compared to full replacements, but getting good results really comes down to checking if the old machinery can handle what needs to be done, especially when dealing with materials such as PLA or those PBAT mixtures that have become popular recently.

Key Materials in Biodegradable Film Production: PLA, PBAT, and Bio-Based Blends

Innovations in Bioplastics: From PLA to PBAT-Based Blends for Film Blowing Machines

PLA and PBAT form the backbone of many sustainable films produced today. PLA comes from fermented plant sugars and gives good rigidity and clarity, although it isn't very flexible. PBAT contains some fossil fuel components but brings needed elasticity and better impact resistance when mixed in. When combined properly, these materials work well together for film blowing processes. They improve how the material behaves when heated and help maintain stable bubbles during extrusion. According to research published in Nature last year, these blended films will completely break down in industrial composting facilities between three to six months, which makes them great options for things like food packaging that don't need long shelf lives. Getting the right results requires careful attention to processing details like screw design and keeping temperatures tightly controlled throughout production runs.

Mechanical and Barrier Properties of Biodegradable Films: Challenges in Processing

The challenge with biodegradable films lies in balancing mechanical strength against barrier performance. Take pure PLA for instance it has decent tensile strength around 60 MPa but stretches only about 6% before breaking, which makes it pretty brittle in real world applications. On the flip side, PBAT material is much more flexible, stretching over 600% in some cases, though this comes at the cost of reduced protection against moisture and oxygen. Blending these materials creates problems if done improperly. Without good compatibilizers, we often see phase separation happening, resulting in weak spots where the film doesn't seal properly and areas that are thicker than others. Another headache comes from moisture pickup during production processes. This absorbed water tends to destabilize the bubble formation while also causing degradation of those precious polymer chains. Film blowing equipment needs special attention here. Manufacturers must incorporate effective drying systems, maintain strict temperature controls within plus or minus 2 degrees Celsius, and invest in better mixing technology to get that uniform dispersion throughout the entire film web. Getting all these factors right ensures consistent mechanical properties from one end of the roll to the other.

Balancing Performance and Sustainability: Overcoming Material Limitations in Film Blowing

For businesses looking to make money from sustainable products, getting the right balance between green credentials and actual performance matters a lot. Take pure PLA for instance it breaks down nicely in compost but takes forever to crystalize, which really slows things down on regular production lines. The industry has come up with some clever tricks though. Adding certain plant-based additives helps speed up that crystalization process so manufacturers can run their machines almost as fast as they do with regular LDPE plastic. Some recent work shows that when they mix PLA with PBAT using special processing techniques, the resulting material tears about 40% better than before according to ScienceDirect last year. Researchers are now trying to find completely plant-based replacements for PBAT since many current versions still contain oil-based ingredients. What we're seeing is companies combining new materials with improved machinery to create biodegradable films that actually work well in flexible packaging applications without compromising on eco-friendly promises.

Resin Selection and Machine Compatibility in Sustainable Film Manufacturing

Matching Biodegradable Resins to Film Blowing Machine Capabilities

Choosing the right resin really comes down to how well it matches what the machinery can actually do. For instance, PLA needs pretty tight temperature control around 160 to 190 degrees Celsius plus special low shear screws so it doesn't break down during processing. On the other hand, those PBAT blends present their own challenges requiring good melt strength management along with reliable haul off systems that stay steady throughout production runs. Today's film blowing equipment should ideally come equipped with adjustable barrel zones, properly designed screw geometries, and effective cooling mechanisms to work within the narrow processing ranges typical of biopolymer materials. Getting this match right between things like melt flow indexes and how sensitive different resins are to heat versus what the machine settings can provide makes all the difference when trying to maintain consistent film quality across batches and reduce unplanned stoppages on the production line.

Customizing Film Properties Through Strategic Resin and Additive Selection

Biodegradable films can actually be customized for different purposes when manufacturers play around with how they blend materials and what additives go into the mix. When PLA gets mixed with PBAT, it makes the film much more flexible and less likely to tear accidentally. And if we throw in some bio-based plasticizers, that helps take away some of the brittleness problem and makes processing easier overall. Want better protection against air and moisture? Some companies are starting to experiment with natural waxes or even tiny clay particles suspended in the material. These little additions work pretty well at keeping things sealed off from outside elements just like regular plastic does. The cool part is that all these modifications still let the final product break down properly in industrial composting facilities. So whether someone needs packaging for fresh produce, mulch sheets for farming, or those lightweight shopping bags people grab at stores, there's now options available that meet both functional requirements and environmental standards.

Overcoming Compatibility Challenges Between Bioresins and Conventional Settings

Trying to run biodegradable resins through standard film blowing equipment brings a whole set of headaches for manufacturers. These bio materials just don't behave the same way as regular polyolefins when it comes to processing parameters. They need much tighter temperature ranges during production and are really sensitive to moisture levels in the environment. Most plants find they need to tweak their setup quite a bit to get decent results. Things like installing better temperature controls, swapping out old gear pumps for ones that handle melt pressure more consistently, and adding those special anti-static lips on the dies all go a long way toward cutting down on defects while keeping production speeds up. Some forward thinking companies have started integrating closed loop feedback systems into their lines too. These smart systems let operators make adjustments on the fly which cuts waste significantly and makes switching between different resin types much smoother operationally. All these modifications mean manufacturers can actually produce quality biodegradable films without having to replace entire production lines, though the upfront investment is still pretty substantial for most small to mid-sized operations.

Environmental Benefits and Efficiency Gains in Modern Film Blowing Technology

Reducing Plastic Waste Through Advanced Film Blowing Machine Efficiency

The latest film blowing machines are making a real dent in waste problems thanks to their smart sensors that keep an eye on film thickness while spotting flaws as they happen. When these automated measuring systems pick up issues, they tweak the extrusion settings right away, which cuts down on defective products and scraps less material overall. A lot of modern setups actually feed recycled plastic back into the extrusion line itself, forming what the industry calls closed-loop systems that align with circular economy goals. Beyond just saving money on materials, these improvements mean plants can report better sustainability numbers year after year, something that matters increasingly to both regulators and environmentally conscious customers.

Lowering Carbon Footprint: Data-Driven Sustainability in Biodegradable Film Production

Cutting down on carbon emissions in biodegradable film manufacturing really depends on adopting energy saving tech. Take servo driven motors for instance they use about half the power compared to old school hydraulic systems. And those variable frequency drives? They adjust power consumption according to what the production line actually needs at any given moment. Then there's multi zone heating equipped with PID controllers which helps keep heat loss to a minimum. Some plants also install heat recovery systems that basically grab wasted warmth and put it back into the process. All these improvements together mean fewer greenhouse gases going into the atmosphere plus real money saved on electricity bills. For companies moving away from traditional plastic products, this makes going green not just environmentally responsible but financially smart too.

The Shift from LDPE to Compostable Films: Environmental Impact and Industry Trends

Switching from LDPE to compostable films represents a major turning point for circular packaging solutions. Traditional polyethylene just hangs around forever, but these new biodegradable options made from stuff like PLA, PBAT, and various plant-based mixes actually disappear entirely when processed at industrial composting sites. That helps tackle the problem of plastic waste sticking around for decades. The switch is happening fast across multiple industries thanks to both government regulations pushing companies forward and customers who increasingly want greener alternatives. Food service businesses are jumping on board first, followed closely by agricultural operations and retailers looking to clean up their environmental footprint. Better machinery now makes it possible to produce compostable films that work just as well as regular plastics when it comes to strength and appearance. They can even be printed on without issues, so manufacturers don't have to completely overhaul their production lines to make the changeover happen smoothly.

Industry Leadership: Pioneering Sustainable Innovation in Film Blowing Machines

Ruian Xinye Packaging Machine Co., Ltd: Driving Change in Eco-Friendly Film Solutions

Companies such as Ruian Xinye Packaging Machine Co., Ltd stand out among those pushing boundaries in eco-friendly film tech. What makes them different is their work on special blowing systems made just for biodegradable stuff, even tricky mixes like PLA and PBAT. The equipment they build comes with really accurate temperature controls, screws designed to handle materials gently without breaking them down, plus smart sensors that adjust based on how these bio-based plastics behave when heated. All these improvements mean better quality products come off the line consistently, less wasted raw materials during production runs, and faster manufacturing speeds for compostable packaging options. As more businesses look to reduce plastic waste, companies like this one are helping make the switch from traditional plastics to greener alternatives actually possible at scale.

Case Study: Custom Biodegradable Film Lines with Precision Control for PBAT Blends

In a recent case study, custom film blowing tech showed real promise when tackling tricky PBAT-based materials. What stood out was how stable the bubbles remained throughout production runs, with thickness staying pretty consistent at around 2% variance even when running those fully biodegradable resins non-stop. The folks behind this setup added automated controls and constant thickness checks so they could tweak things on the fly while still keeping quality high. Compared to old systems that had been modified for similar work, these results were night and day. When looking ahead at expanding green packaging options, it becomes clear why investing in specialized equipment makes all the difference for manufacturers trying to meet sustainability goals without compromising on output.

Technological Advancements in Temperature and Output Stability for Sustainable Production

Today's film blowing equipment comes equipped with multiple temperature zones and sophisticated cooling mechanisms designed specifically for working with temperature sensitive biopolymers. These upgrades help maintain proper melt strength while controlling how the material crystallizes, resulting in films that have consistent structures throughout their surfaces something manufacturers need to get those important mechanical characteristics right. With IoT monitoring systems built into many modern machines, plant operators can predict when maintenance will be needed and tweak parameters on the fly as conditions change. This has led to better machine availability rates and energy savings around 15% in most facilities according to industry reports. For companies making biodegradable films, these tech advancements make both financial sense and environmental sense at the same time, pushing the boundaries of what's possible when it comes to producing sustainable packaging solutions that actually work well in real world applications.

Frequently Asked Questions (FAQ)

What are the benefits of using biodegradable films in packaging?

Biodegradable films offer environmental benefits by breaking down naturally, reducing plastic waste, and minimizing long-term pollution. They are also suitable for industrial composting, effectively decreasing the carbon footprint.

What challenges do manufacturers face when producing biodegradable films?

Manufacturers encounter difficulties in processing biodegradable films due to their unique thermal and rheological behaviors, which require precise temperature controls and specialized machinery adjustments.

How are traditional film blowing machines retrofitted for biodegradable film production?

Traditional machines can be upgraded by replacing standard screws with low shear options, enhancing temperature controls, and incorporating efficient drying systems to improve performance and material consistency.

What are key materials used in biodegradable film production?

PLA and PBAT are essential materials for biodegradable films, often blended to balance properties such as rigidity, flexibility, and impact resistance, while ensuring compostability.

Table of Contents

- The Evolution of Film Blowing Machines for Biodegradable Film Production

- Key Materials in Biodegradable Film Production: PLA, PBAT, and Bio-Based Blends

- Resin Selection and Machine Compatibility in Sustainable Film Manufacturing

- Environmental Benefits and Efficiency Gains in Modern Film Blowing Technology

- Industry Leadership: Pioneering Sustainable Innovation in Film Blowing Machines

- Frequently Asked Questions (FAQ)