1. Customer Company Profile & Case Overview Customer Name: GreenPack Solutions Ltd.Industry: Flexible Packaging ManufacturingLocation: Berlin, GermanyBusiness Scope: Production of eco-friendly plastic bags, vest bags, and cust...

View More

Customer Name: GreenPack Solutions Ltd.

Industry: Flexible Packaging Manufacturing

Location: Berlin, Germany

Business Scope: Production of eco-friendly plastic bags, vest bags, and custom packaging solutions for retail and industrial use.

GreenPack faced rising demand but struggled with:

Low production speed (240 bags/min on old machines).

High energy consumption and material waste.

Frequent downtime due to mechanical failures.

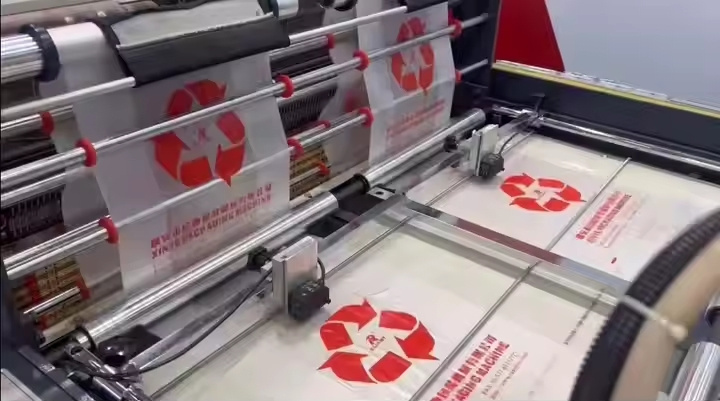

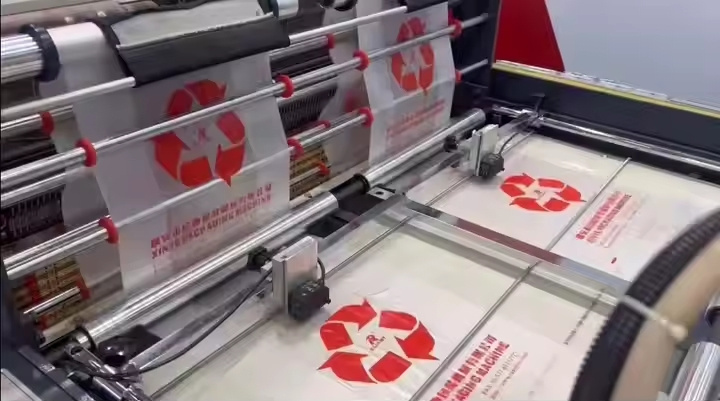

Our Fully Automatic Dual-Line High-Speed Vest Bag Making Machine was installed, featuring:

Double-line production (400 bags/min total).

AI-based precision control reducing material waste by 15%.

Energy-efficient motors cutting power costs by 30%.

Statement from GreenPack’s Production Manager, Klaus Weber:

*"Switching to this machine was a game-changer. We doubled output while lowering costs. The auto-error detection system reduced downtime by 40%, and the bags’ consistency improved significantly. The after-sales team provided excellent training and support."*

Key Feedback:

✔ Speed: 400 bags/min vs. 240 previously.

✔ Reliability: 99% uptime after 6 months.

✔ ROI: Achieved in just 8 months.

Category |

Details |

Sector |

Flexible Packaging Manufacturing |

Application |

Retail/Industrial Vest Bags |

Market |

Europe (Eco-focused Brands) |

Week 1: Machine installation & staff training.

Week 2: Test runs & fine-tuning.

Month 3: Full production at 200 bags/min.

Metric |

Old Machine |

New Machine |

Improvement |

Speed (bags/min) |

240 |

400 |

+66% |

Energy Consumption |

15 kW/h |

10.5 kW/h |

-30% |

Material Waste |

5% |

3.5% |

-1.5% |

Downtime Rate |

8% |

1% |

-7% |

24/7 Remote Monitoring for predictive maintenance.

Spare Parts Guarantee: Delivered within 48 hours in Europe.

Annual Upgrades: Free software optimizations.

Green Pack’s success highlights how our dual-line high-speed vest bag machine boosts efficiency, cuts costs, and supports sustainable production. The 400 bags/min output and 30% energy savings make it ideal for mid-to-large packaging manufacturers.

Interested in a similar solution? Contact Us Today.

Copyright © 2025 Ruian Xinye Packaging Machine Co.,Ltd | Privacy policy