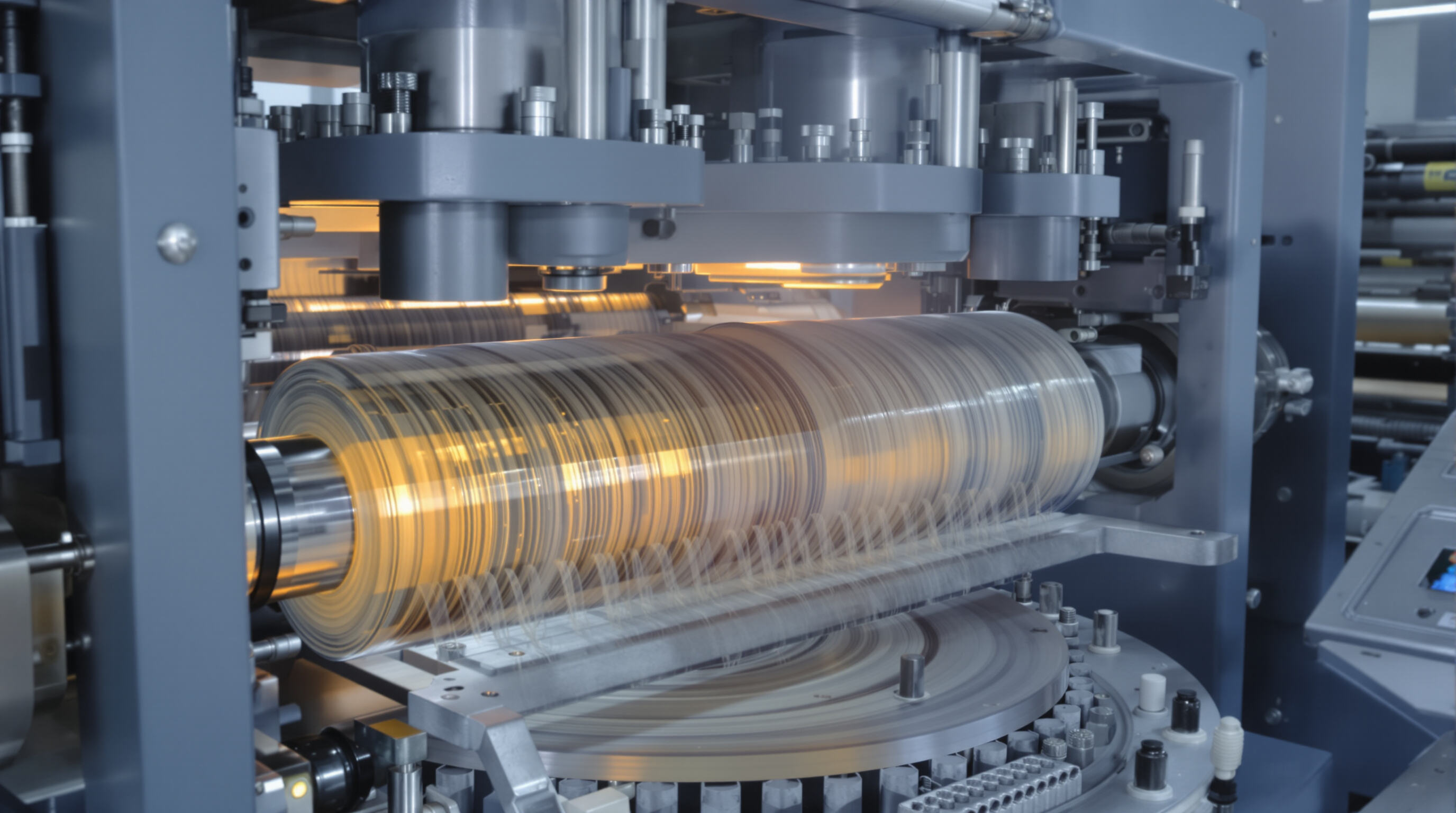

In the plastic packaging industry, film blowing machines are essential production equipment, widely used in food packaging, industrial packaging, agricultural film, and daily necessities packaging. As market demands for film performance and production efficiency increase, traditional single-layer film blowing machines are increasingly unable to meet diverse demands. ABA film blowing machines, with their unique structural and process advantages, are becoming the preferred choice for a growing number of manufacturers.

1.How ABA Film Blowing Machines Work: Layered Structure and Design Innovation

1.1 What Is an ABA Configuration in Multi-layer Blown Film Machines?

ABA film blowing machines work with what's called a three layer co extrusion process. The outer layers are made from the same polymer material (layer A), while the middle layer (layer B) is something different altogether. Most machines need two separate extruders for this setup. One machine handles just the middle layer, and another takes care of both sides at once. Take HDPE for example. Many manufacturers choose this stuff for the outside because it stands up well against wear and tear. But inside? That's where they often throw in cheaper materials like calcium carbonate or even recycled plastic waste. Some factories manage to get away with putting up to half recycled content in there without compromising quality too much.

1.2 Layer Ratio Control (e.g., 1:11:1 vs. 1:3:1) and Its Impact on Film Uniformity

The way layers are proportioned makes a real difference in how films perform and what they cost to produce. When we talk about a 1:11:1 configuration, that means there's a pretty hefty middle section ideal for those tough industrial films that need to hold their shape. The 1:3:1 setup works better when products require balanced strength throughout without weak spots. Modern ABA equipment comes equipped with these dual die arrangements that keep each layer's thickness right around 5% variance or better. This level of control delivers much more reliable results than old school mono layer methods, which tend to have all sorts of material irregularities showing up in the final product.

1.3 Structural Differences Between ABA and Mono-layer Film Blowing Machines

Unlike mono-layer machines that rely on a single extruder, ABA systems feature:

- Dual extruders: Enable precise control over layer composition by separating material flows

- Asymmetric distribution systems: Deliver core-layer materials without disrupting outer-layer stability

- Modular die designs: Allow rapid adjustments for varying layer ratios or resin types

This configuration produces films that are 15–20% stronger than mono-layer equivalents while using 30% less virgin polymer—supported by industrial trials showing tensile strength of 38 MPa for ABA films versus 32 MPa for mono-layer versions.

2.Enhanced Film Performance: Strength, Durability, and Precision Thickness Control

2.1 Mechanical Advantages of the Sandwich-Layer Architecture

The ABA sandwich structure creates a synergistic bond between layers. High-performance outer layers distribute mechanical stress, while the inner core absorbs impact energy. This design improves puncture resistance by up to 30% compared to mono-layer films, all while preserving ductility and flexibility.

2.2 Optimized Outer Layers for Superior Film Strength and Tear Resistance

By concentrating premium resins in the outer layers, ABA films achieve tear resistance exceeding 50 N/mm² without excess material use. These surface-engineered films perform exceptionally in demanding environments—such as pallet stretch wrapping and heavy-duty sack production—where mono-layer alternatives often require thicker gauges to match durability.

2.3 Advanced Dual Die Control for Consistent Thickness Distribution

Precision is achieved through dual-die systems with real-time thickness monitoring and closed-loop feedback, maintaining uniformity within ±2%. This tight tolerance surpasses the ±7% variation typical of single-die systems, ensuring consistent mechanical properties across the entire film roll.

2.4 Case Study: Tensile Strength Comparison in Industrial Packaging Applications

In simulated palletized cargo transport, ABA films demonstrated a tensile strength of 137 N/mm², significantly higher than the 89 N/mm² recorded for mono-layer films. This enhanced strength reduced in-transit product damage by 40% and supported 22% higher stacking loads, proving the performance advantage in real-world logistics.

3. Cost Control Advantages

3.1 Cost-Effective Raw Material Utilization

Single-layer film blowing machines can only use a single raw material. Improving film performance requires selecting higher-grade materials, which increases production costs. ABA film blowing machines, however, offer flexible combinations:

Layer A uses virgin material to ensure appearance and strength;

Layer B uses recycled or filler material, significantly reducing costs while maintaining overall performance.

This design effectively resolves the trade-off between performance and cost.

3.2 Recyclable Raw Materials

Layer B often uses recycled material, which not only reduces production costs but also aligns with environmental trends and meets the requirements of green and sustainable development.

3.3 Higher Return on Investment

Although the equipment investment for ABA film blowing machines is higher than that of single-layer machines, they save raw materials, reduce losses, and increase the added value of the film during production, resulting in significantly better overall economic benefits.

4.Application Versatility and Resin Compatibility of ABA Machines

4.1 Processing Flexibility with LLDPE, LDPE, and PP Blends

ABA machines work with all sorts of different resins such as linear low density polyethylene (LLDPE), regular low density polyethylene (LDPE), and good old polypropylene (PP). The modular die system lets manufacturers tweak the melt flow rate separately for each layer, which means they can handle materials ranging from very runny ones with melt indexes around 0.5 g/10 min right up to stiffer stuff at about 4 g/10 min. What makes these machines so valuable is their ability to combine different properties in one product. For instance, creating films with rigid PP cores wrapped in flexible LLDPE layers works great for stretch wrap applications where we need both stickiness and strength against tears. Industry data from the latest 2024 Industrial Film Processing Report shows something interesting too: nearly seven out of ten operators say they don't experience major issues when moving production between virgin LDPE and those tricky recycled post industrial PP blends.

4.2 Tailoring Films for Stretch Wrap, Agricultural, and Construction Uses

The ABA technology allows for tailored solutions depending on specific applications. When making stretch wrap, manufacturers often incorporate soft LLDPE on the outside to hold loads better, paired with a sturdy PP center that stands up to fast production speeds. Farmers benefit too when their plastic films have UV protected LDPE tops covering biodegradable materials underneath. This combination makes greenhouse covers last around 30 to maybe even 40 percent longer before needing replacement. The construction industry sees advantages as well. ABA creates vapor barriers between 80 and 120 microns thick with outer layers that resist heat damage. These multi-layered products show about 23% greater tensile strength according to ASTM D882 tests compared to regular single layer options available on the market today.

5.Sustainability Benefits of ABA Film Blowing Technology

5.1 Integrating Recyclates Without Compromising Film Quality

With ABA machines, the process works by putting recycled stuff right in the middle layer, but keeping the virgin polymer intact on top and bottom surfaces. What this means is manufacturers can actually get away with using about half recycled material without running into problems like weaker tear resistance, cloudy appearance, or compromised barrier properties that plague those single layer systems so much. The end product turns out to be pretty decent quality film that still works great for things like covering crops or wrapping industrial products, despite having quite a bit of recycled content mixed in there.

5.2 Reducing Plastic Waste Through Thinner, Stronger Films

The multi-layer structure increases puncture resistance by 30%, enabling 15–20% gauge reduction without performance loss. Thinner films directly reduce plastic consumption; one automotive stretch wrap line achieved 23 metric tons of annual resin savings. Lighter packaging also lowers transportation emissions, contributing to circular economy goals through source reduction.

5.3 Long-Term Environmental and Economic ROI vs. Higher Initial Investment

The initial cost for ABA equipment runs roughly 40 percent higher compared to standard mono layer systems, but most companies find they get their money back within around 18 to maybe even 36 months depending on usage. When it comes to materials, there's real savings happening too. Using recycled content along with better thickness control cuts down what we pay for resins each year somewhere between 18 and 25 percent. Looking at the big picture through lifecycle studies reveals something pretty impressive actually – about 32 fewer grams of CO2 emitted for every kilogram of film made this way. That kind of environmental footprint reduction isn't just good for the planet either. It helps meet those ever tightening regulations while also giving manufacturers a leg up against competitors who haven't made similar improvements yet.

Frequently Asked Questions (FAQs)

1. What materials can ABA film blowing machines process?

ABA machines are compatible with resins like LLDPE, LDPE, and PP, allowing versatility in production for various applications.

2. How do ABA film blowing machines improve sustainability?

They incorporate recycled materials in the core layer, reducing plastic waste and enhancing the environmental impact without compromising film quality.

3. What are the advantages of ABA over mono-layer film systems?

ABA film blowing machines offer improved strength, reduced material usage, and better thickness control, providing enhanced performance at lower costs.

Table of Contents

- 1.How ABA Film Blowing Machines Work: Layered Structure and Design Innovation

- 2.Enhanced Film Performance: Strength, Durability, and Precision Thickness Control

- 3. Cost Control Advantages

- 4.Application Versatility and Resin Compatibility of ABA Machines

- 5.Sustainability Benefits of ABA Film Blowing Technology

- Frequently Asked Questions (FAQs)