Dynamics of Modern Plastic Sack Making Machines

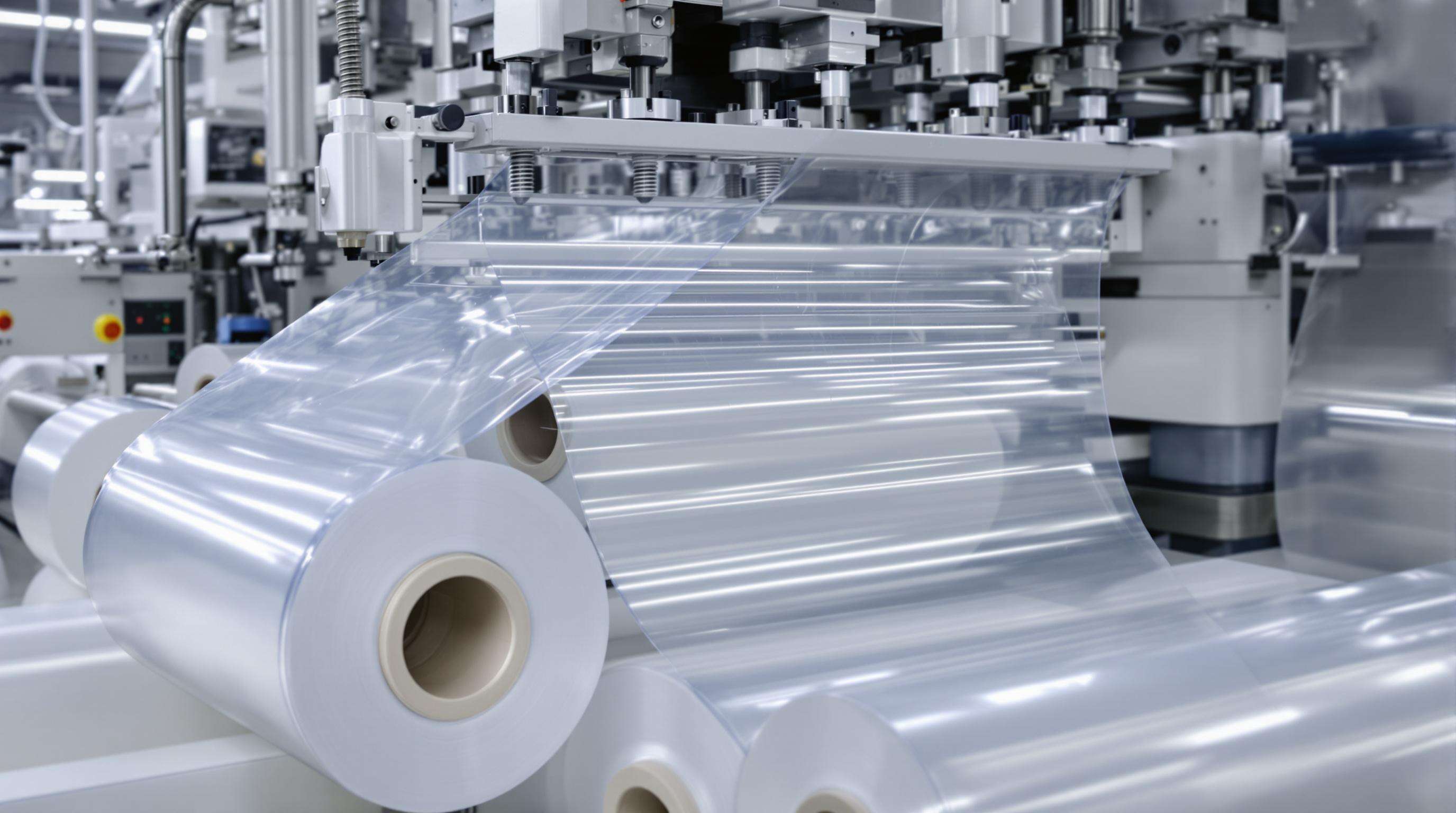

Modern plastic sack making machines integrate cutting-edge technologies to address evolving sustainability demands and operational efficiency. These systems combine high-speed automation with material science innovations to balance throughput requirements and waste reduction, while minimizing energy consumption and accommodating recycled polymers.

Integrated Automation Systems Revolutionizing Production

Intelligent automation governs extrusion-to-packing workflows, with self-optimizing controls reducing human intervention. Real-time sensor arrays monitor polymer viscosity and thickness tolerance, enabling adaptive adjustments during operation—decreasing defect rates by 34% in validation studies while lowering manpower requirements by 60%. Implementation challenges persist in technical training and cybersecurity frameworks for interconnected equipment.

Throughput Metrics: Speed vs Quality Balance

Throughput optimization requires precise calibration between speed and stability. High-output machines achieving 120-150 sacks/minute must maintain consistent seal integrity, especially when processing recycled resins. Studies indicate exceeding 5% speed fluctuations leads to 22% higher rejection rates. Advanced torque limiters and tension sensors maintain precision sealing thresholds at high velocity.

Technological Convergence in Packaging Lines

Robotics and edge computing enable seamless sack handling, printing, and stacking coordination. Integrated vision systems inspect defects at 0.1mm resolution, triggering real-time corrections without halting production. Synchronized servo motors eliminate tension conflicts in multi-layer sacks, reducing micro-stops by 73%—critical for e-commerce packaging agility.

Core Engineering in High-Output Sack Machinery

Extrusion Technologies Driving Material Efficiency

Advanced extrusion systems optimize polymer flow control, reducing material waste by 8-12% (Packaging Institute 2022). Multi-layer die designs ensure uniform thickness distribution while accommodating LDPE, HDPE, and recycled polymers without compromising film strength—key for cost-effective, sustainable operations.

Sealing Mechanism Innovations for Variable Polymers

Adaptive temperature-pressure algorithms ensure consistent bond strength across diverse materials, including biodegradable films and recycled polymers. With contamination-resistant coatings, these mechanisms maintain seal integrity at over 120 cycles/minute—critical given recycled polymer usage has risen 38% since 2020.

Precision Web Control Systems Analysis

Laser-guided tension regulation and servo-controlled rollers reduce film breaks by 15-25%, maintaining ±0.2mm tolerance during material transitions. Closed-loop feedback compensates for environmental variables like humidity, enabling 10% annual film savings from optimized side-seam overlap.

Energy Consumption Benchmarks in Operations

Modern machinery reduces kWh/kg ratios by 20-30%. Variable-frequency drives cut standby consumption by 45%, while regenerative braking recaptures 15% kinetic energy—helping high-output equipment achieve €0.25 kWh per kg of LDPE processed in line with global sustainability targets.

Global Adoption Patterns in Packaging Upgrades

Regional trends highlight diverging priorities—developed economies adopt high-automation machines for sustainability compliance, while Asia-Pacific favors throughput-intensive models for e-commerce growth. Global Packaging Machinery Insights projects Asia-Pacific spending to grow at 7.2% CAGR through 2026.

Regional Manufacturing Cost Variations

Operational expenditures vary widely:

- Western markets incur 30-45% higher costs from compliance tech

- Southeast Asia offers 20-28% lower TCO via local supply chains

- Latin America balances skilled labor costs with feedstock proximity

Operational Complexities in Sack Production Systems

Material Science Challenges with Recycled Polymers

Recycled polymers introduce 25% more extrusion defects due to contamination and inconsistent melt flow. AI-powered impurity detection and compatibilizer additives help stabilize production when recycled content exceeds 30%.

Industry Paradox: High Speed vs Customization Demands

Standardized production achieves 99% uptime but struggles with small-batch custom orders. Modular machinery helps offset the 18–24% efficiency loss from frequent changeovers.

Maintenance Protocols for Continuous Operation

Proactive strategies keep downtime below 2%: vibration sensors prevent gearbox failures, while blockchain repair logs ensure 92% first-time technician accuracy—critical with $5k/hour downtime costs.

Strategic Advancements in Sack Making Machinery

AI-Driven Predictive Maintenance Integration

AI forecasting reduces maintenance costs by 30% and extends equipment lifespan by 25% through real-time performance optimization algorithms, scheduling interventions during natural workflow pauses.

Sustainable Production System Innovations

Regenerative drives cut power use by 18% per metric ton, while solvent-free sealing and closed-loop cooling align with circular economy targets.

Trade Show Innovations Shaping Equipment Design

Recent expos highlight modular quick-change assemblies (40% faster retooling), IoT quality analytics, and hybrid woven/non-woven designs—key for flexible, traceable production.

Future-Proofing Sack Equipment Investments

Modular designs with standardized interfaces allow incremental upgrades, while IoT connectivity enables predictive maintenance (extending lifespans 15–20%). Hybrid extrusion modules handling mixed polymers at <15% efficiency loss prepare operations for tightening regulations—balancing sustainability with long-term cost control. Cloud-based firmware ensures continuous integration of AI enhancements without full system replacements.

FAQ

What are the key benefits of modern plastic sack making machines?

Modern machines integrate automation to reduce human intervention, optimize throughput, and minimize energy consumption while supporting sustainability goals with recyclable polymers.

How do these machines balance speed and quality in production?

They use advanced torque limiters and tension sensors to maintain consistent seal integrity even at high speeds, preventing rejection rates from exceeding acceptable percentages.

How is material waste reduced in modern extrusion systems?

Through optimized polymer flow control and multi-layer die designs that ensure uniform thickness distribution, resulting in an 8-12% reduction in material waste.

What role does AI play in sack making machinery?

AI enhances predictive maintenance, reducing costs and extending machine lifespan by optimizing performance in real-time and scheduling timely interventions.

Table of Contents

- Dynamics of Modern Plastic Sack Making Machines

- Integrated Automation Systems Revolutionizing Production

- Throughput Metrics: Speed vs Quality Balance

- Technological Convergence in Packaging Lines

- Core Engineering in High-Output Sack Machinery

- Extrusion Technologies Driving Material Efficiency

- Sealing Mechanism Innovations for Variable Polymers

- Precision Web Control Systems Analysis

- Energy Consumption Benchmarks in Operations

- Global Adoption Patterns in Packaging Upgrades

- Regional Manufacturing Cost Variations

- Operational Complexities in Sack Production Systems

- Material Science Challenges with Recycled Polymers

- Industry Paradox: High Speed vs Customization Demands

- Maintenance Protocols for Continuous Operation

- Strategic Advancements in Sack Making Machinery

- AI-Driven Predictive Maintenance Integration

- Sustainable Production System Innovations

- Trade Show Innovations Shaping Equipment Design

- Future-Proofing Sack Equipment Investments

- FAQ