Technology Fundamentals of Blown Film Extruders

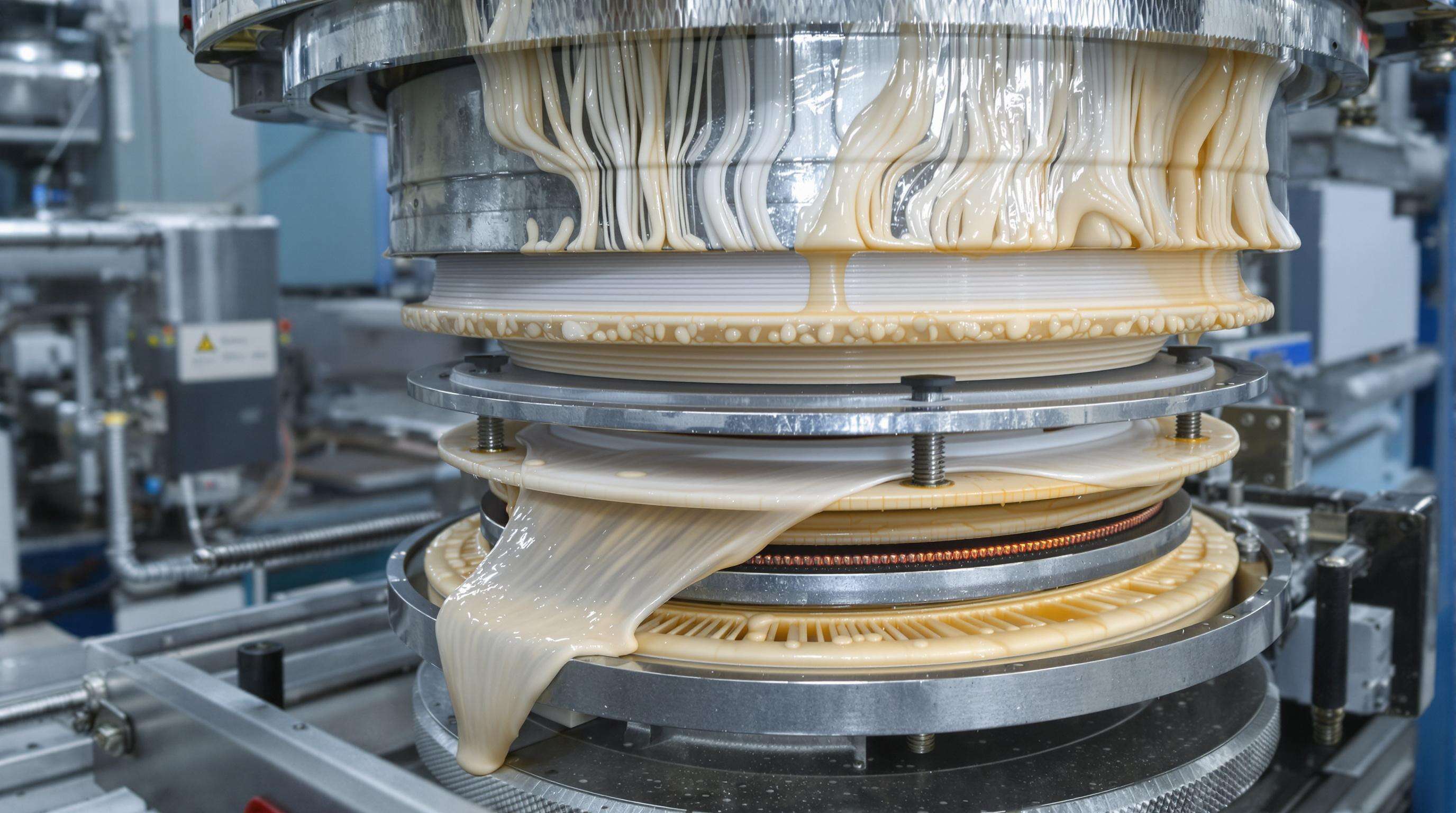

Co-Extrusion Process Mechanics in Multi-Layer Systems

Blown film extruders merge molten polymers into layered films with distinct functional properties through synchronized flow rates and temperature control. Modern systems achieve layer thickness variations of ±2%, enabling precise barrier customization for applications like food packaging.

Material Compatibility in Three-Layer Film Structures

Polyethylene (PE) and polypropylene (PP) form stable outer layers, while ethylene vinyl alcohol (EVOH) often serves as a moisture-resistant middle layer. Incompatible melt viscosities or thermal expansion coefficients can cause delamination, reducing puncture resistance by up to 40%.

Key Components: Dies, Screws and Air Rings

- Dies: Spiral mandrel designs minimize weld lines for consistent thickness

- Screws: Barrier screws with mixing zones optimize melt homogeneity

- Air rings: Dual-lip cooling systems stabilize bubble geometry at 15–20°C/sec

Performance Metrics for Co-Extrusion Efficiency

Industry benchmarks include output yield (kg/hr), layer uniformity (±5% target), and energy consumption (kWh/kg). Advanced extruders achieve 98% material utilization through real-time viscosity monitoring, cutting waste by 25% compared to single-layer systems.

Advantages of Co-Extrusion in Flexible Packaging

Barrier Enhancement for Product Protection

Layered structures combining EVOH for oxygen resistance with polyethylene for moisture protection extend food shelf life by 30–50% (Three Layer Co-Extrusion Blown Film Machine Market Report 2024).

Material Optimization and Cost Reduction

Strategic layering reduces raw material costs by 15–20% while maintaining functionality, achieving thickness reductions of up to 25% in flexible packaging.

Durability Improvements Through Layer Engineering

Adding nylon sublayers improves puncture resistance by 40% in heavy-duty applications, reducing film failure rates by 18% in stress tests.

Market Growth Drivers for Blown Film Extruders

Surge in Demand for Multi-Layer Packaging Films

The global blown film extruder market grows at 7.2% CAGR through 2032, as 63% of manufacturers now prioritize 5-7 layer films for advanced protection.

Regional Production Hubs and Consumption Patterns

Europe accounts for 34% of high-precision extruder deployments, while Southeast Asia houses 42% of flexible packaging converters. North America and Europe represent 58% of premium barrier film demand.

Industry Paradox: Sustainability vs. Performance Demands

While 82% of converters use PCR materials, only 39% achieve target performance metrics with 30% recycled content, accelerating R&D in compatibilizer additives.

Technological Innovations in Blown Film Extruders

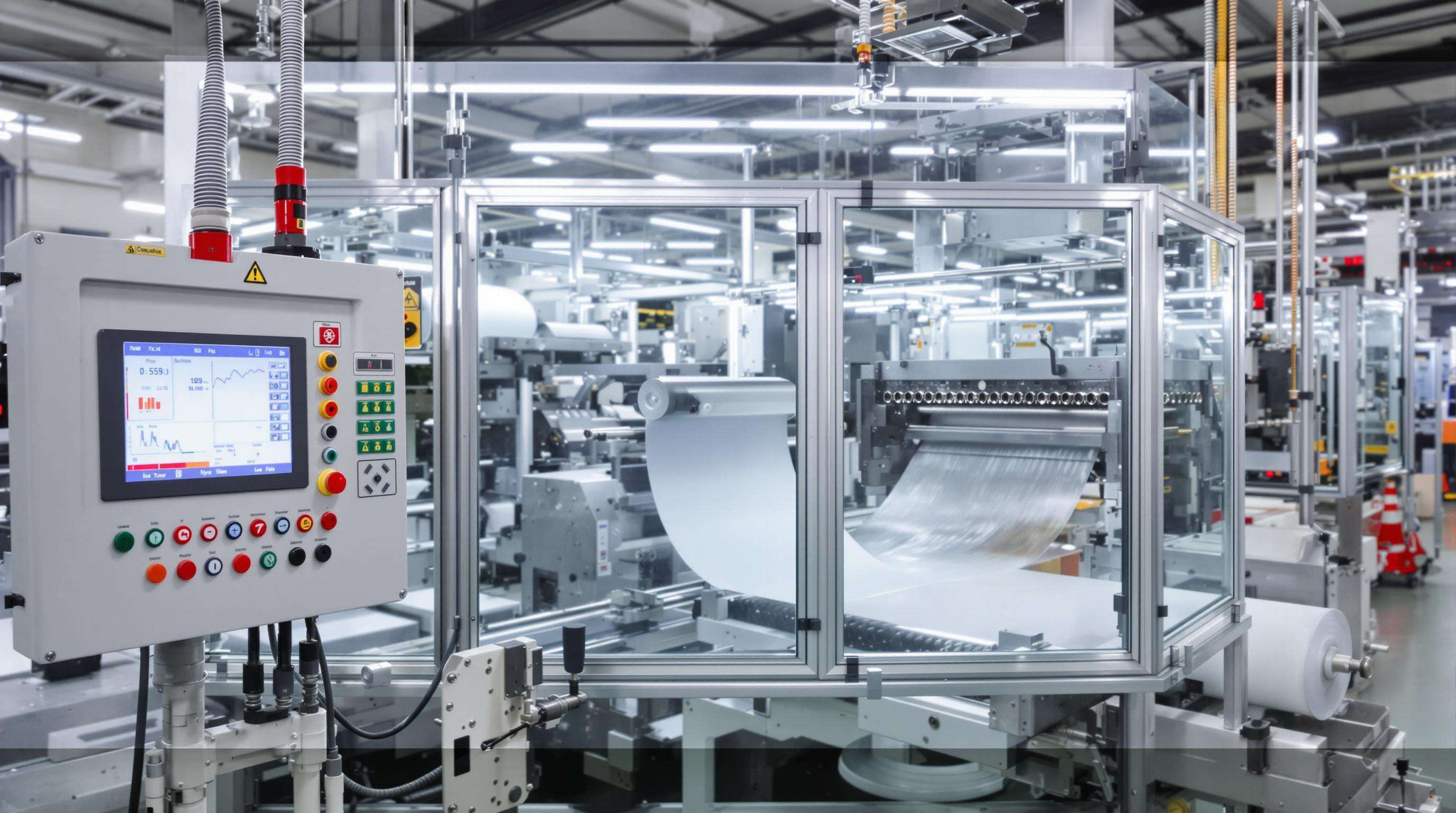

Intelligent Control Systems for Layer Precision

Closed-loop feedback mechanisms adjust layer ratios in real-time, reducing material waste by 12–18% and enabling 7-layer barrier films under 25 microns.

Energy-Efficient Drive Technologies

Regenerative AC drives cut power consumption by 23%, while hybrid heating systems maintain ±1°C temperature stability.

Real-Time Quality Monitoring Solutions

In-line spectrometers detect contamination within 0.7 seconds, and machine vision systems prevent 92% of downstream packaging rejects.

Sustainability Trends in Blown Film Extrusion

Recyclable Material Developments for Co-Extrusion

Over 60% of manufacturers now prioritize biodegradable polymers like PLA, reducing fossil fuel dependency by up to 40%.

Regulatory Impact on Packaging Standards

The EU’s Circular Economy Action Plan mandates designs with over 95% recyclability by 2025, pushing extruder operators to optimize layer compatibility.

Carbon Footprint Reduction Strategies

Energy consumption has dropped by 18–22% since 2020 through optimized screw designs and variable-frequency drives, cutting emissions by up to 35%.

Blown Film Extruders in Packaging Industry Evolution

Integration with Circular Economy Models

74% of manufacturers incorporate material recovery systems, achieving up to 92% reclaimed polymer utilization in three-layer structures.

Future-Proofing Through Modular Designs

Modular extruders feature:

- Interchangeable dies for 200mm to 4m film widths

- Retrofit-ready drive systems cutting energy use by 18%

- AI-guided layer thickness control within ±2 microns

This flexibility reduces changeover waste by 38% and enables output variations from 500 kg/h to 2,500 kg/h.

FAQ

What is co-extrusion in blown film extruders?

Co-extrusion involves the combining of multiple layers of molten polymers to form a single film with diverse functional properties, crucial for applications like food packaging.

Why is material compatibility important in co-extrusion?

Material compatibility ensures stability in the film structure, preventing delamination and enhancing puncture resistance.

How do advanced extruders achieve high material utilization?

Advanced extruders use real-time viscosity monitoring, which significantly reduces material waste and increases material utilization efficiency.

What are the benefits of layered structures in packaging?

Layering enhances product protection, reduces raw material costs, and improves durability.