In the plastic packaging industry, film thickness uniformity is a key indicator of blown film quality. Uneven thickness can lead to reduced mechanical properties, insufficient transparency, unstable shrinkage, and even affect printing, lamination, and subsequent processing. Thickness uniformity is even more crucial for demanding applications such as food packaging, pharmaceutical packaging, agricultural films, and industrial films. Achieving and maintaining excellent thickness uniformity on extrusion blown film lines has become a key priority for blown film companies in enhancing their product competitiveness.

1.Understanding Thickness Uniformity and Its Impact on Film Quality

1.1 Defining Extrusion Blown Film Line and Its Role in Product Performance

How evenly film thickness is distributed matters a lot for how well it performs mechanically. Premium applications usually keep variations within about plus or minus 5%. This affects things like tensile strength and how good the barrier properties are. When looking at polyethylene films specifically, if there's more than 0.5 mil difference in thickness (which equals roughly 12.7 micrometers), tests show puncture resistance drops between 18 to 22 percent according to ASTM D1709 standards. Getting consistent thickness isn't just important for looks either. Packaging materials need this consistency, same goes for agricultural films and those heavy duty industrial liners. Maintaining even thickness helps meet ISO 9001:2015 requirements too, which most manufacturers have to follow these days anyway.

1.2 Key Factors Influencing Blown Film Quality and Process Stability

Four primary variables affect thickness consistency in extrusion blown film lines:

- Melt temperature fluctuations (±3°C) leading to flow instability

- Die lip contamination causing localized flow restriction

- Asymmetric air ring cooling that deforms the bubble

- Resin viscosity mismatches in multi-layer coextrusion

According to the Journal of Plastic Film Technology (2023), 83% of gauge variations originate from uneven melt distribution at the die head, underscoring the need for precision in flow control.

1.3 Common Defects Caused by Non-Uniform Thickness in Extrusion Blown Film Line

Persistent thickness inconsistencies (below 90% uniformity) lead to significant operational and quality issues:

| Defect Type | Consequence | Remediation Cost Factor |

|---|---|---|

| Bubble instability | ±35% output reduction | $1,200/hr downtime |

| Wrinkles | 15–20% material scrapping | $8.75/kg polymer waste |

| Weak heat seals | 22% higher customer returns | $3.4M/yr quality claims |

Automated monitoring systems mitigate these defects by correlating real-time thickness profiles with process adjustments, enhancing stability and reducing waste.

2.Die Head Design and Melt Flow Control for Consistent Film Gauge

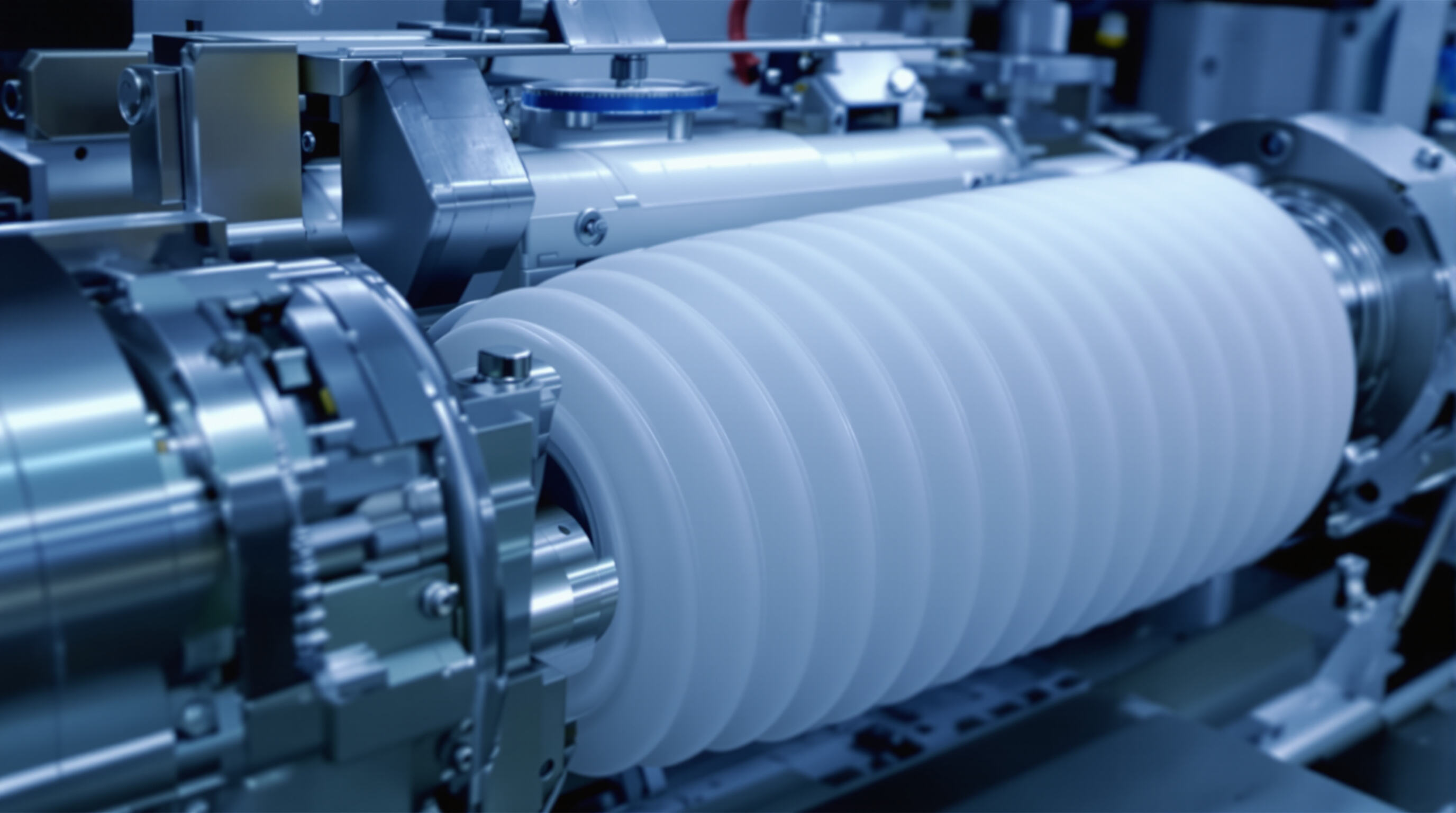

2.1 Role of Precision Screw and Die Design in Achieving Uniform Extrusion

Performance in modern extrusion blown film lines depends on engineered screw geometries and die configurations. Precision screws with optimized compression ratios promote homogeneous melt formation, minimizing viscosity-driven thickness fluctuations. When paired with spiral mandrel die designs, these systems achieve circumferential flow uniformity within ±2% under controlled conditions.

2.2 Importance of Die Gap Uniformity in Thickness Control

Die gap consistency is directly linked to film gauge stability. A deviation as small as 0.05mm across the die circumference can result in a 12% thickness variation in the final film. Advanced dies integrate real-time thermal compensation to maintain gap tolerances below 10μm, ensuring consistent output during extended production cycles.

2.3 Balancing Melt Flow Distribution to Minimize Gauge Variation

Asymmetric flow patterns are responsible for 63% of thickness defects in blown film operations. Systems utilizing controlled material flow technologies achieve 40% tighter thickness tolerances by streamlining melt channels, optimizing shear rates, and preserving laminar flow.

2.4 Fixed vs. Adjustable Die Lips: Evaluating Performance in Modern Systems

While fixed die lips offer mechanical simplicity, micro-adjustable lips with 0.001mm resolution are increasingly standard in modern systems. Integrated with automated thickness monitoring, these actuators dynamically adjust lip positions to maintain gauge uniformity within ±1.5% across roll changes and resin batch transitions.

3.Air Ring Cooling and Bubble Stability in Blown Film Extrusion

3.1 How advanced air ring systems enhance cooling and film uniformity

Advanced air ring technology ensures uniform cooling through precisely controlled, high-speed airflow around the polymer bubble. This promotes stable crystallization, reduces uneven stress distribution, and minimizes thickness variation. By maintaining optimal frost line height, these systems reduce material memory effects and improve optical clarity—critical for high-visibility packaging applications.

3.2 Managing asymmetric airflow to improve thickness control system reliability

Uneven cooling remains one of the main culprits behind those frustrating gauge variations we see across the circumference, often going beyond the 4% threshold. The solution? Proper placement of air ducts combined with careful control of airspeed distribution helps balance things out around the bubble during processing. Today's advanced equipment incorporates these smart dynamic louvers that actually adjust themselves according to what they sense from thickness measurements in real time. This automatic correction eliminates those annoying spiral deformations and brings thickness consistency down to around 1.5% variance. That's quite a leap forward compared to old fashioned manual adjustments which were never really accurate enough for modern production standards.

3.3 Dual-lip and oscillating air rings for optimized bubble stability

The dual lip air ring design creates focused cooling areas that help solidify both the inside and outside layers of the bubble at the same time, which stops those annoying drag caused vibrations. These special oscillating versions actually move air around as needed to fight off changes in viscosity while things are happening, kind of working like shock absorbers for the process. Real world tests from manufacturing plants indicate that this setup cuts down on balloon like instability problems by about two thirds when compared to regular single lip systems. The result? Thickness differences stay under 0.75 percent even when running at top speeds, something that makes plant managers very happy indeed.

4. Application of Advanced Technologies

4.1 Automatic Thickness Control System (AUTO GAUGE)

This system uses infrared or beta-rays to measure film thickness distribution online and feeds data back to the die head heat bolt or automatic air ring, enabling real-time adjustments and significantly improving circumferential uniformity.

4.2 Internally Cooled Bubble Control (IBC)

This system controls the airflow and temperature within the bubble, achieving more precise bubble stability and thickness adjustment, particularly suitable for wide-width film production.

4.3 Automatic Dosing and Feeding System

This system ensures a stable ratio of raw materials and additives, avoiding thickness fluctuations caused by uneven manual dosing.

5. Production Management and Operational Key Points

- Pre-startup inspection: Ensure the die head, air ring, and cooling system are clean, and ensure the screw and barrel are functioning properly.

- Process Monitoring: Monitor melt pressure, take-off speed, and air ring air volume at all times to ensure stable operation.

- Regular Maintenance: Regularly disassemble and clean the die head and clean the air ring vents to maintain optimal equipment condition.

- Personnel Training: Operators should be familiar with the principles of thickness adjustment to avoid blind adjustments that could cause greater fluctuations.

Frequently Asked Questions

1.Why is thickness uniformity important in film manufacturing?

Thickness uniformity impacts the mechanical performance of films, affecting tensile strength, barrier properties, and reducing defects such as puncture resistance loss.

2.What factors influence thickness consistency in blown film lines?

Key factors include melt temperature fluctuations, die lip contamination, asymmetric air ring cooling, and resin viscosity mismatches.

3.How can defects due to thickness inconsistency be mitigated?

Automated monitoring systems help correlate real-time thickness profiles with process adjustments to enhance stability and reduce waste.

4.What role do modern technologies play in maintaining gauge control?

Technologies such as laser sensors, AI-driven optimization, and IoT-enabled systems play a crucial role in maintaining tight thickness tolerances and improving process efficiency.

Table of Contents

- 1.Understanding Thickness Uniformity and Its Impact on Film Quality

- 2.Die Head Design and Melt Flow Control for Consistent Film Gauge

- 3.Air Ring Cooling and Bubble Stability in Blown Film Extrusion

- 4. Application of Advanced Technologies

- 5. Production Management and Operational Key Points

- Frequently Asked Questions